Managing Construction Risk Through Pre-Operational Planning

Discrepancies in performance, losses or incidents happen, but are they accidents? Has the organization really stopped to analyze why projects or processes are experiencing disruptions, inefficiencies, accidents, and losses? Why are workers not meeting expectations or getting hurt in spite of standards, programs, policies, procedures, training, and possibly everyone’s best efforts? How can the situation be remedied without expending considerable time and resources? What can be done to reduce deviation from good practices and organizational expectations so as to improve performance reliability and optimize the bottom line? These are important considerations which need to be addressed in a time when industry is under greater pressure to increase efficiency and effectiveness.

Typically, safety is treated as a discrete and separate function within the contractor’s organization. Much of what we do in safety revolves around accidents. We try to avoid them. We use programs and other strategies to help us control their adverse effects. We train our workers on how to work safely. We measure our success by comparing our loss data to national statistics. Our accidents and losses impact our cost of risk and ultimately our very competitiveness in a highly competitive industry. This also may well impact our ability to market construction services and secure work. Accidents usually do not happen due to fate or intent on the worker’s part. They happen because of ineffective processes, inadequate procedures, poor planning or lack of foresight. Therefore we must get away from the predominantly worker-focused intervention common in the industry, and look into areas over which the worker has little or no control over but are contributing to unwanted outcomes.

One of the key objectives of any business is to make a profit. The best way safety can assist in achieving this is through alignment with the organizational goals and objectives. That can only be achieved by its seamless integration into the operations. We need to approach safety from a risk management as well as operational and systems perspective. We also need to ensure that appropriate planning is conducted before the start of operation so as to addresses the potential hazards of the job by evaluating organizational procedures, practices and systems which foster the creation of risk.

Pre-Operational Planning Process

Planning is an integral part of contracting and the construction process. Virtually every aspect of construction involves some form of planning. Successful contractors are generally effective planners. It is through proper and effective planning that the appropriate materials are secured, delivered, and installed. It is though the process of planning that all the trades work harmoniously on the site. Without effective planning, all the diverse elements, aspects and functions of construction would not come together to result in the final finished product—the building.

- Pre-operational planning is the review of planned operations before and during the construction process to identify and eliminate potential sources of loss.

- The goal of preplanning is to reduce hazards, which will minimize disruption, increase efficiency and lower costs.

So, if incidents on the construction site cause disruptions and losses, then it begs the question: Can we apply the fundamentals of planning to safety and therefore minimize these undesirable outcomes? Fortunately, the response is YES; so let’s look at the planning process and see how we may affectively integrate safety management into the contractor’s operational as well as logistic planning.

Preplanning justification

A research study conducted by the Construction Industry Institute (CII) in the 1980s identified the single most effective tool a construction company has to prevent accidents on their work sites as pre-project/pre-task planning. A follow-up study covering a much larger group of contractors by them in the 1990s arrived at the same conclusion. See the CII website for further information.

Construction projects are dynamic in nature, and involve a large number of diverse organization who come together to build it. Planning is a necessary management tool with which to marshal, manage and control the resources—workers, material, and equipment. Safety, also, is a managed process, just like any other in the construction business. One would not dream of “running” the job without a plan. And safety management should be treated in the same manner. Pre-operational planning is proactive in nature. You manage people, resources, events and accident-causing situations based on a plan. By being proactive, you try to anticipate problems (loss sources) and plan to minimize their impact or all together eliminate them.

Pre-Operational Safety Planning Process

The goal of preplanning is to reduce risks, which will minimize disruption, enhance flow, increase efficiency, and lower costs. Pre-operational safety planning involves the integration of safety into the construction operational plans and procedures. It looks at potential risk in the operational and logistic plans, construction procedures, or work processes and either eliminates them or provides for controls that will minimize their adverse effect. Exposures resulting from procedures and work methods are anticipated, and reviews of applicable safety program elements are made to make sure that the operations are in compliance with the intent of the program, as well as see if they are addressed by the program. In a nutshell, preplanning looks at the when, how, who, where and what of the construction process with an “eye” on safety outcomes.

Preplanning Timing

The pre-operational safety planning process can be performed at four distinct times in the life of a project. These are before the bid or the pre-construction effort, before any work is started in the field, at the beginning of each major phase of construction, and before each individual task. The greatest value of this effort comes about if it is conducted at the earliest possible time in the life of a project.

At Bid Stage

This is the most effective time to address potential safety concerns on a construction project, because they can be identified, eliminated, and/or budgeted for most effectively. One may even decide not to bid a project, thereby avoiding the taking on of potentially unacceptable risks.

At Job Mobilization

This is where risks can be addressed at a time when few commitments have been made and it is easiest to make holistic changes to the project. This is the time to address the interfaces of the operations of various subcontractors. This is also the time and place to get the most “bang for your safety buck.”

At Pre-Operations Stage/by Job Phase

This phase allows you to fine-tune your previous plan. By this time, you may have more detail available to you, so you can address more issues in greater detail. Also by this time some of the subcontractors are “on board” and can contribute to the risk evaluation and mitigation process.

Special Operations/Tasks

You may have unique situations that require special attention, such as helicopter lifts, etc. These need to be addressed in great detail and contingency plans drawn up to address the potential exposures.

The pre-operational safety planning process is accomplished at three levels: Globally for the complete project, for specific operations with high risk and exposure potential, as well as for each individual task. Obviously, it is most beneficial to look at the whole project as that is the time for arriving at the most effective and all encompassing solutions.

Who Should Be Involved in Preplanning?

All the folks involved in the different disciplines in constructions—estimating, planning, purchasing, cost control and field operations—need to be involved in this process at certain given times.

The Estimator

This is the person in your company who first sees the job. He/she has to evaluate the job risks and budget for them.

The Safety Director/Safety Coordinator

This person should be consulted at the bid stage to help evaluate risks that the estimator has not identified or appreciated the seriousness of. Safety also provides input as to how to most effectively and cost efficiently provide the necessary controls. The safety director brings to the table familiarity with the safety standards and other local regulations.

Project Manager/Job Superintendent

This person provides scheduling, site layout input and may select equipment. They may also help select subcontractors. These inputs are under the purview of the contractor and should be evaluated for any unique risks that they may bring to operations in the field.

Other Management

There may be special requirements imposed on the project by the owner. Your company may have rules that are not common to the industry, and your organizational structure may have special requirements that should be reviewed and addressed at this time.

Insurer/Broker Loss Control Representative

This is a resource available to contractors in the preplan of their operations. The broker/insurer may have a great deal of in-house information and expertise that the contractor can draw on. The contractor should assess the capabilities of its broker or insurer in providing assistance in this area.

How To Preplan

There are four phases of the preplanning process: fact finding, analysis and evaluation, the preplan meeting, and follow through.

Fact Finding

The sources to get information are from the project plans and specifications, the contract, and the owner’s requirements. Another source is the “means and methods” the company or the subcontractors are planning to use as well as the operational, logistic and tactical plans. Other areas to consider are the site and its adjacencies, including local ordinances, traffic patterns, public usage and other neighborhood realities.

Analysis and Evaluation

The things that need to be evaluated and analyzed are the potential for worker injuries, both the contractor’s and the subcontractor’s workers. Other things that need to be addressed are the potential harm to the public, as well as damage to property both in and around the job site.

The Preplan Meeting

The key to an effective and efficient meeting is preparation. Everyone must do their “homework” before attending the meeting. At the meeting’s conclusion, there must be agreement as to what the risks are and what controls are going to be implemented. The result of this meeting will be an action plan for the control of risks, hazards and exposures.

Follow Through

Of course, for any plan to work, there must be following through. Inspections must be conducted to ensure that controls are put in place and that they are sufficient to address to existing conditions. If there are changes, then modifications are made to meet the changed conditions.

What Do You Preplan for?

You “plan” for everything that has risks that are not acceptable to the organization. Through the planning process, you identify these risks, then eliminate them or try to reduce their adverse effect to the lowest possible level. To best address what to preplan, a general checklist should be created to assist the participants in addressing all possible areas involving risk.

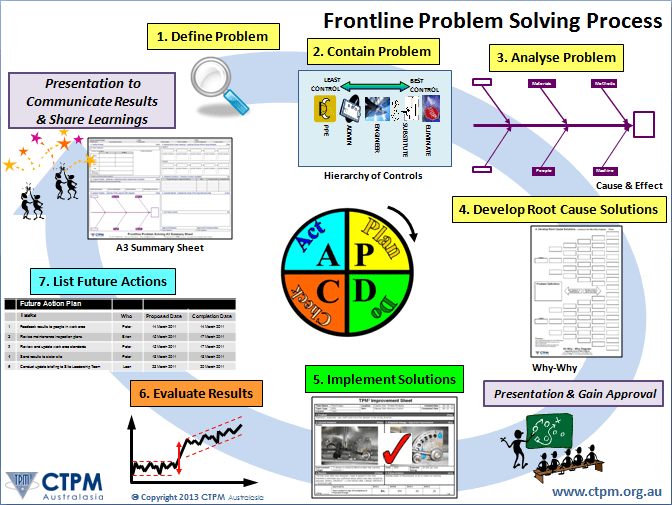

The preplanning process, if properly done, is a “continuous improvement process.” It starts with the identification of areas of risk, through the collection of data. The risks are then analyzed. Solutions are found that will address the risks. The solutions are then evaluated for effectiveness and if they meet project needs. The “best” solution is selected and then implemented. Audits are conducted to ensure that the implemented solution is effective and “working.” If it is, then the process is taken to the next risk element; and if not, then it is revaluated and the process starts all over again.

Summary

Preplanning is the review of planned operations before and during construction in order to identify and eliminate potential loss sources. The goal of preplanning is to reduce hazards, which will minimize disruption, increase efficiency and lower costs.

Mr. Furst, President at The Furst Group, has over 15 years of experience consulting to a variety of firms, including architects, engineers, construction, service, retail & manufacturing organizations. He has provided guidance in the design & implementation of innovative integrated organizational strategic and tactical solutions resulting in efficiencies along the value stream, utilizing Six Sigma, Lean and balanced scorecard metrics optimizing human and business performance. He has also provided motivational presentations at various organizations to all levels of management and employees. Some of the consulting was with Liberty Mutual Group customers helping them manage their safety program more effectively and efficiently, thereby improving business outcomes as well as substantially reducing their cost of risk.

Contact him at peter.furst@gmail.com