Building Operational Excellence

Operational Excellence in hard times – a distraction or an imperative?

The crash in the economy is requiring everyone to re-evaluate their position and make decisions on what they need to do differently. For many, it will require a fundamental re-thinking of how to go about business; the challenge is to plan and ride out the immediate need for survival and develop a strategy to exploit the opportunities that still exist.

This article presents a case for making operational excellence a key strategic lever for recovery. It will explore the subject by asking 3 questions:

1. WHY is the pursuit of operational excellence valid?

2. WHAT are the principles and methodologies that need to be in place?

3. HOW do you approach the change process to maintain the necessary pace and ensure sustainability of the solution?

No manufacturer is immune to the effects of the economic crisis and no one can really predict what lies ahead. The loss in confidence is affecting everyone, with even the exemplary ‘benchmark’ manufacturers being hit by shrinking demand for products, from consumers switching to cheaper products in the grocery market to postponing the replacement purchases for durable goods.

A tactical focus is the response of many in such times in a bid to maintain a holding position or simply to survive. It is tempting to simply slash and burn to get an immediate short term gain. Drastic measures such as reducing budgets, work shifts, headcount and squeezing supplier payment terms can produce the easiest and most obvious cost reduction measures, but be cautious about cutting costs at the expense of generating low morale with employees and souring relationships with those who may be core in your drive for future growth. Businesses will need to take a much broader view to address the fundamentals of how to better manage the end to end supply chain.

For many businesses which are in the process of implementing new ‘ways of working’ there will be the inevitable challenge around whether the business is following the right path as the sense of urgency quickens. It is right for businesses to remain prudent; however I would argue it might also be the most opportune time to adopt Lean and implement operational excellence. If driven appropriately, even in this downturn, a company can gain competitive advantage and emerge as a more agile player when the upturn comes.

Operational excellence is a straightforward concept; it means doing things well along the entire supply chain and across all functions of the operation whilst striving for profitable growth.

The pursuit of operational excellence has never been more pressing and should not be optional. For those businesses that have already embarked on their journey to operational excellence, it is time to redouble the effort and, for those who are yet undecided, it is time to stop dithering and look at how to turn the challenges they face into opportunities.

There is still a vast array of untapped potential in all organizations and operational excellence can provide one of the critical levers to accelerate the pace of change for businesses. There is no golden bullet or miracle cure to ride out the current economic downturn and individual businesses will need to focus on different aspects of their operation to exploit the opportunities.

1.0 WHY is the pursuit of operational excellence valid?

Whatever the scale of intervention, whether a single site or across a group, there has to be a compelling reason to take action and everyone needs to understand ‘WHY?’. To answer the case for adopting an operational excellence approach, consider 3 points:

1.1 What is the cost benefit? Making the link back to profitable growth.

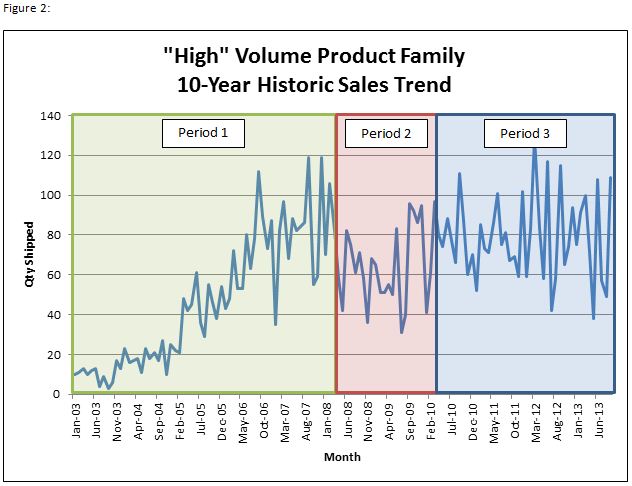

1.2 Mind the gap – where are you now? Understanding your current position.

1.3 Why wouldn’t you? Tough times require tough action.

1.1 WHAT is the cost benefit?

Organizations face many challenges that need to be solved right now. It is how to continue to provide the existing product or service, offering what the customer wants when they want it, while maintaining margin. The ability to react quickly is essential and requires visibility of the opportunities beyond the monthly management accounts and should include measures that highlight the prospects for maintaining and improving growth and return on investment over the longer term.

An initial ‘go see’ to assess the actual situation will enable you to decide where to drill down and adopt the best strategy to realize the benefits. It will require the deployment of core tools to expose and quantify the potential wins and assess what is worth exploiting, both in terms of controlling costs and generating future value.

Further analysis to understand the impact on the bottom line and how it becomes normal business may be required. Creating a sustainable solution requires the building of a stable, yet flexible platform where everyone can pursue and be involved in a proactive and ongoing agenda to further improve the ability to:

- Effectively drive the day to day operation – control costs

- Unearth greater future value from the business – generate extra profit

- Maximize their cash (both in terms of fixed assets and working capital)

Generating extra profit can so often be achieved by getting closer to the customer and really understanding what they value (and are prepared to pay for) and ensuring the operation (in its broadest sense) really works to solve customer problems and deliver an improved total service offering.

Being clear on the size of the opportunity makes it easier to present a compelling case to take action, especially when there is a clear plan to realize the savings. Making this transparent is essential to support a call for action and enables everyone in the business to better understand why the company has mapped out the direction it has for improvement.

It will be the businesses that are able to adapt that will be able to prosper in the current climate, regardless of which sector they operate in. It will be those that are able to link their current operational and financial activities with where they need to get to over the next few years that will be able to best plan for the future.

1.2 Mind the gap – where are you now?

Operational excellence should be seen as a journey with a clear road map against which you can measure progress and see where to go next. To both close the current performance gaps and ensure the sustainability and consistency of results requires the development of a robust business operating system and the development of exceptional practices.

Using an assessment is recommended in order to get transparency of where the business and individual units are now. An assessment acts as a guide to select which areas to work on next to close the gaps and helps get a common understanding when prioritising the building blocks for improvement.

There has to be consistent development towards the vision to take away any ‘knee jerk’ reactive action that may impact on the long term benefits. The challenge is to get the right balance between results and practices. Too much focus on results by relying either on a few key individuals or adopting a hit squad approach may get a short term gain but, without investing in developing capability and the appropriate business systems it will not be sustainable. Equally excessive focus on practices without making the link to results will have a similar effect and has no place today.

1.3 WHY wouldn’t you do it?

Whether working at either a strategic or tactical level, the leadership should be challenging their thinking in terms of:

Exploiting opportunities – Is the overall size of the opportunity explicit and understood? To make real gains, whether freeing up cash, controlling costs or building value, organizations have to adopt a strategic perspective. It cannot be done by simply targeting everyone with a straight percentage improvement across the business. It is necessary to take a holistic approach, evaluate the size of the prize, rapidly look at the facts and ‘go see’ in each area to understand the implications of taking action and the knock on effect through the business.

Real collaboration – Are the synergies of working as ‘one team’ maximized?There needs to be joined-up thinking; it is too easy for managers to migrate back into their silos for self preservation. They ignore the implication of taking isolated improvement actions in their area without considering the knock on consequences of their actions to the full value streams.

Working smarter – Is there goal alignment with clarity of focus on the right priorities with the right resource? Ultimately, it is about building the capability of groups of people rather than relying on a hit squad approach, giving the local team the skills to make the improvements sustainable, incorporating any improvement into the day job.

Maximum engagement – Are all employees engaged and motivated to deliver the vision? Whatever methods you choose to cut costs, release cash or add value, you need to take your front-line managers with you and involve them in the process. It is their commitment and buy-in to the activity that will determine whether their teams will take the necessary action to deliver the desired outcome.

Dynamic but disciplined environment – Are people held to account for their actions or inaction? This activity should be done at pace and having established the facts, measures should be put in place to track the deliverables. This should be both integrated into strategy deployment and the regular performance review process to maintain the momentum. The toughest challenge is to maintain improvements through clear accountability.

The case for incorporating the above thinking is logical and common sense. Imagine walking into your business when everyone could answer yes to the above questions. What would it feel like and what would you see? These questions are ones that can be used to check alignment on the way to deliver the business goals within your own team.

These are exceptional times and the call for action needs to be at all levels and in all areas of the business. Operational excellence gives the structure to bring together all initiatives into a one team, one plan approach.

2.0 WHAT are the principles and methodologies that need to be in place?

There is still a vast array of untapped potential in all organizations and operational excellence provides one of the critical levers to accelerate the pace of change for businesses. There are many different routes, theory and methodologies available to support the delivery of these opportunities and the transformation to excellence.

2.1 How does it fit with what we do now? Building on what is good, not wholesale replacement.

2.2 What is the right balance between tools and behaviors? Looking beyond the tools.

2.3 Do you have a culture that promotes problem solving? Getting to the root cause(s).

2.1 How does it fit with what we do now?

The solution needs not be too prescriptive and should build on what is in place and working well, integrating new practices as needed to drive business improvement. The challenge is to make sure it delivers the right outputs.

The leadership challenge is to move away from reacting to problems to a position where leaders spend the majority of their time carrying out systematic continuous improvement and thinking strategically rather than continuing the vicious ‘fire fighting’ cycle.

In order to improve the likelihood of lasting change, a stepped approach is required; doing things at the right time and in the right order. The methodology is about people and process, with an emphasis on developing the right behaviors not simply deploying more tools. Many of the tools will often have been tried before so it will not be about reinventing the wheel or introducing a new technique, but instead, it is about getting the wheels back on the bus.

5 Levels describe the phases an organization progresses through on its journey to excellence. The rate at which a business moves up the Levels will vary and it is not untypical that different parts of the organization will mature at different speeds.

Through assessment and challenging the current ways of working against the model you will see where the gaps are and what to focus on next. The journey should start with getting the foundations in place including: establishing the appropriate organizational structure, getting the right players on the pitch and being explicit about job roles, measures and targets. Having the foundations will set the boundaries to enable people to take control at the right level and start to get basic systems in place which will then create the platform to improve. An operation at a stable Level 3 will have the reliability, predictability and capability to manufacture.

Beyond Level 3, the mindset of individuals is to exceed expectations with all functions seeking to optimize products, processes and people with the development of an increasingly customer focused culture.

2.2 WHAT is the right balance between tools and behaviors?

There must be an appropriate balance between developing tools and associated behaviors that ensure sustainability of the tools. Process improvement without paying attention to the people and organizational culture issues will lead to a robotic adoption of proposed changes without substantial commitment to them.

The tools are only of use if understood and applied as part of the day job. It should start with a focus on the operational basics and include tools such as measures, data capture, SOPs, performance reviews (hourly, daily, weekly and monthly), communications and quality management. For those at a more advanced stage, once a high degree of natural challenge, openness, collaboration and teamwork are in place, it is appropriate to expose them to the more sophisticated tools in order to sharpen their performance.

The key is to be able to choose the right tools for the job, applying a few things well to make a real difference. Many core tools are common sense. If we can engage people and excite them about performance improvement, they will reach the conclusion themselves. In most cases the tools are easy to understand, but getting them embedded into ‘the way we do things’ is more difficult. Most of the change effort will need to go into influencing the behavior change rather than tool development.

Investing time in developing a common toolbox made up of core tools is worthwhile in the short term to support the training, coaching and review of staff. Over time the toolbox should then evolve into a group operating system that acts as the reference point for the ‘way of working’.

Many of the tools in the Lean toolbox have a common theme which is linked to the activity and process of problem solving in order to improve performance. The organizations that foster a ‘no blame’ culture, where the focus is on understanding the flaws in the process rather than rooting out the individual to blame will be best positioned to engender a ‘problem solving’ culture.

The pace at which an organization can adapt to rigorous and effective problem solving will depend on many factors and starts with the leaders, leading from the front and demonstrating by doing, adopting the principles of effective problem solving. By applying ‘go see’ to understand the problem, gathering further data, getting to root cause and then experimenting with potential solutions in the right place will help demonstrate a real understanding of what good looks like and more importantly demonstrate management’s commitment to the process.

2.3 Do you have a culture that promotes problem solving?

Arguably, embracing problem solving is the biggest win organizations can get in the short term; mobilizing their employees to better utilize their innate knowledge and expertise in their processes. Developing an individual’s capability to lead the full problem solving cycle will take time, but getting everyone involved in elements of the process (measurement and data capture) can start today. Educating everyone in basic problem solving has to be a worthy medium term goal.

Think of the power of having a common approach where everyone applies the same steps to get to the root cause and then applies and makes standard the 100 year fix (best solution). It requires the development of everyone’s capability in the problem solving tools, with the appropriate supportive environment to enable problems to be solved at the right level of the organization.

The top tips act as a prompt to challenge people to think about what is important and attempts to make it simple for staff to understand and apply them.

Imagine what it would be like if…

Everyone in the organization understood what their measures and targets were and how they could take action to improve their results. Everyone understood what was in their control; the kit (machinery), consumables and directs (materials), the process (method) and the people (manpower). Everyone had clarity in what they were expected to do – now, today, this week, this month and this year – in steady state and when in crisis!

To support these foundations and to help everyone drive the measures at the right level requires a process that is transparent where people can see how their area is performing and what actions are in place to resolve the issues and close the performance gap. Everyone adopts a go see approach to manage their area and solve problems; an environment where everyone respectfully challenges themselves and others to take the appropriate action.

People are clear on their ‘top 3’ opportunities and prioritize to exploit the biggest wins through resolving the root cause of problems with the best solution that we currently know – the 100 year fix then becomes standard. With effective use of visual management, everyone can make decisions on what to do next. If we could get to this point, we would be operating a stable Level 3, with a problem solving mindset that would provide the platform to optimize and excel.

The most successful players develop a strategic vision that maps out the journey to turn uncertainty into opportunity.

3.1 Why will this be different? A holistic and integrated approach.

3.2 What level of commitment is required? Understanding the leadership role.

3.3 How do you ensure that the journey to operational excellence is a success? Keeping the program on track.

3.0 HOW do you approach the change process to maintain the necessary pace and ensure sustainability of the solution?

Successful implementation of Lean thinking depends on the organization’s ability to develop a holistic approach, incorporating process understanding with employee engagement. The output of this will result in an integrated, joined up program that will lead manufacturing on a sustainable and common journey to operational excellence.

The program must be a strategic priority, have a clear strategic FRAMEWORK that is aligned to the business vision and sets out the roadmap for the journey. The framework will help to direct focus and should provide guidance to what needs to be done.

3.1 Why will this be different?

People need to have the right tools to deliver the expected results; the TOOLS & TECHNIQUES when used appropriately will help them see more clearly, measure, focus, problem solve, collaborate and as a result, be more effective. Ultimately, this can develop into the group operating system.

In order to embed exceptional practices, it is more about changing mindset than tools (80:20), developing a culture which encourages enabling BEHAVIORS. Self discipline and ownership are key attributes for everyone, for it is this that maintains the processes’ sustainability.

The program must be driven; management need to apply energy and attention to the critical activities to MAKE IT HAPPEN. This requires robust program management and includes activities such as governance, tracking and strong change management.

To mobilize the organization and ensure that operational excellence is embedded in its widest sense requires a balanced approach to implementation, with each element of the approach running in parallel.

As the diagram illustrates, to fail on one or more of the elements of the approach will lead to a suboptimal program. Recognising this risk at the start of the operational excellence journey will enable management to mitigate against the risk of failure.

3.2 WHAT level of commitment is required?

A prerequisite for success is to have clarity around the expected commitment that people need to make; after all, it is about embedding a ‘way of working’ that involves everyone throughout the organization.

The case for making a commitment to resourcing the operational excellence program appropriately should be based on the logic of adopting a structured approach, which when applied will be the ‘way of working’ not an add on ‘initiative’.

Imagine if everyone in the business was fully aligned to the vision with a clear framework that mapped out a roadmap for change. How would the leaders at each level of the organization be operating?

It starts with senior management taking on specific and appropriate responsibilities with a real understanding of what their aspirations are with regard to operational excellence. They would be seen to give direction, focus and:

– Provide vision and set strategy

– Demonstrate visible commitment

– Provide resources (£, people, time)

– Reinforce the vision

At the same time, line managers have a critical role too and are the change leaders within the organization. They will be helping to facilitate the process and need to:

– Lead and coach the operational change

– Set priorities

– Set standards

– Reinforce the method

Front line teams also have a key part to play and will foster an environment that encourages everyone to:

– Carry out improvement activity

– Work to standard

– Be part of a team

– Spot opportunities

3.3 HOW do you ensure that the journey to operational excellence is a success?

The WHY – WHAT – HOW cycle needs to be brought together. The diagram highlights the critical success factors that will make the program great and requires a heavy commitment from management.

A key output of the ‘WHY?’ should be a roadmap outlining the journey plan and route to the compelling business case of operational excellence and its benefits. The delivery of this ‘strategic framework’ will be most effective when there is strong strategic alignment; in simple terms, through the adoption of a one team, one plan approach that is endorsed by the board.

As with strategy, having a common language for tools and the improvement processes and making it standard work will make control and challenge easier and ensure new practices are embedded more quickly.

All of the above is best reinforced by all leaders in the organization exhibiting ‘enabling’ behaviors. The maturity of the organization (the level of team performance) will influence the level of resource that must be put in place to make things happen.

Other fundamentals include recognizing success, communicating progress and, unless already normal practice is best done in a structured way, by integrating it into the change activity. Keeping it simple and relevant to the audience is good advice. For example, remembering the following mantra will help maintain momentum:

– What gets measured gets done

– What gets talked about gets done first

– What gets rewarded gets done best

Program management goes far beyond Microsoft project and, whilst it does not have to be complicated, it does require an investment in the right level of resources for it to work best. Starting by getting the right infrastructure in place will pay dividends later when trying to keep the program on track. Like any investment, thorough up-front planning will reduce the level of rework later and ultimately accelerate the pace of change.

Program governance is another aspect of making it happen that doesn’t always get the focus it merits, until things go wrong! If done well, it will give the structure from which all other change activities can hang and it does encourage the right behaviors, discipline and challenge. Regular steering groups should take place to review progress to plan, address blockages, champion the program and confirm the next steps. In parallel, all results (savings and benefits), audit and assessment scores should be tracked, reported and communicated against targets to make progress transparent.

Finally, even if the organizational tendency is to revert to fire fighting when dealing with today’s crisis, it is essential that there is a continuous check and measure against the long term strategy of sustainable change. This is best done through ‘go see’, by being there.

4.0 Conclusion

There is no easy fix. This article has put a case forward that clearly promotes operational excellence as a proven approach to support the delivery of profitable growth and sustainable change – even in hard times.

For many, short term survival will be the only agenda item right now, that may lead them down a purely cost cutting route. The risk is that cost cutting in isolation will become a downward spiral that will ultimately lead to business shrinkage. The sustainable answer requires longer term strategic thinking.

The economist, Dr. David Fleming succinctly captured what is required at a recent conference, “Large-scale problems do not require large-scale solutions – they require small-scale solutions within a large scale framework.” The WHY – WHAT – HOW cycle does just that and provides the structure that enables the delivery of solutions at both a macro and micro level.

How do you stack up?

- Do you have a compelling vision and strategy for sustainable growth?

- Are you clear how you will further improve the day to day operation, unearth future value and maximize your cash?

- Are your continuous improvement, teamwork, Lean tools and techniques well honed, used extensively and targeted at your profit improvement plan?

- Have you built a real momentum in the organization with everyone aligned, bought in and striving for the same goals?

- Are you addressing people’s behavior at all levels to ensure the culture supports and enhances your efforts

- Do you have a clear ‘road map’ of progress and know where you are, how you are doing and what you are doing next?

Suiko© 2009

Andy’s varied background in sales, customer service and operations in Toyota among others, allow him an all round understanding of the pressures and demands of leading companies striving for World Class. His work as an Account Manager supporting major blue chip companies and his desire to ‘delight’ customers set him in fine stead to support group change programmes. He thrives on getting people to see things from a different viewpoint and the results are proof of this.

Contact him at Andy.Spooner@suiko.co.uk