Podcast: The Need for Lean Six Sigma in the Public Sector

Joseph Paris, Chairman of XONITEK will address the need for Lean Six Sigma in the public sector. Click here to listen.

Lean Six Sigma is a method that relies on a collaborative team effort to improve performance by systematically removing waste and reducing variation. It combines lean manufacturing/lean enterprise and Six Sigma to eliminate the eight kinds of waste (muda).

Joseph Paris, Chairman of XONITEK will address the need for Lean Six Sigma in the public sector. Click here to listen.

When was the last time you created a Pareto chart manually? For those of you not familiar with a “Pareto ” chart, it is simply a bar chart that organizes the categories from highest-to-lowest in frequency of occurrence. Pareto charts are useful when “issues” outnumber the resources available to solve them; obviously, you would want to put the resources on…

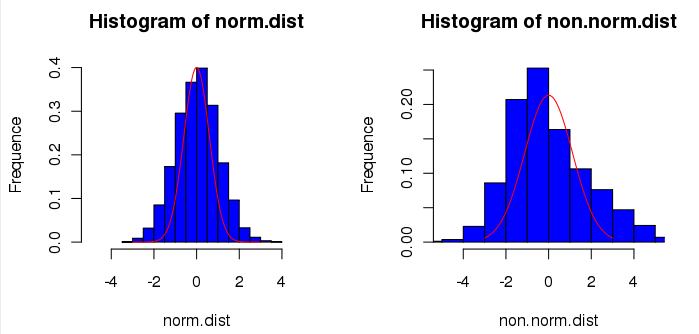

An important aspect of total quality is the identification and control of all the sources of variation so that processes produce essentially the same result again and again. At a glance, a histogram is a tool that allows you to understand a variation that exists in a process. Although the histogram is essentially a bar…

In December 1997, members of the United Nations Framework Convention on Climate Change (UNFCCC) negotiated the Kyoto Protocol that established emissions reductions for the developed and developing nations that ratified the Protocol. The Protocol went into force in February 2005 after Russia ratified it in November 2004. The U.S. did not ratify the Protocol because it set no emission limits for China or India. The Kyoto Protocol…

Fighter pilots, Grunt and Boom, kick it around with PLinc and OpEx Society’s Founder, Joe “JP” Paris and discuss Operational Excellence, Temper Tantrums, Professional Reading and Flowing Robes. This is the INTERNET VERSION of the show, uncut/unedited and with lots of YUKS and CHUCKLES. Click here to listen.

One of the main problems with companies is that their sights are often set too low—using efficiency measures that don’t reflect their operation’s full potential. For example, a recent analysis of 27 manufacturers showed that on average the companies were operating at 71% of their maximum efficiency. However, a deeper analysis based on their assets’ “true…