Succeeding With Lean When You Don’t Know Nothin’

Lean Thinking Fundamentals: The Building Block for a Lean Management System

It is vitally important for lean people to know nothing when it comes to working towards improvement. This sounds like a crazy idea, and it is a 100% turnaround from traditional management thinking. This article discusses the fundamentals of Lean Thinking, a building block when developing your own true Lean Management System.

We will look at:

- How lean thinkers go about radically improving their business

- Engaging everybody to make improvement

- Increase and capture knowledge

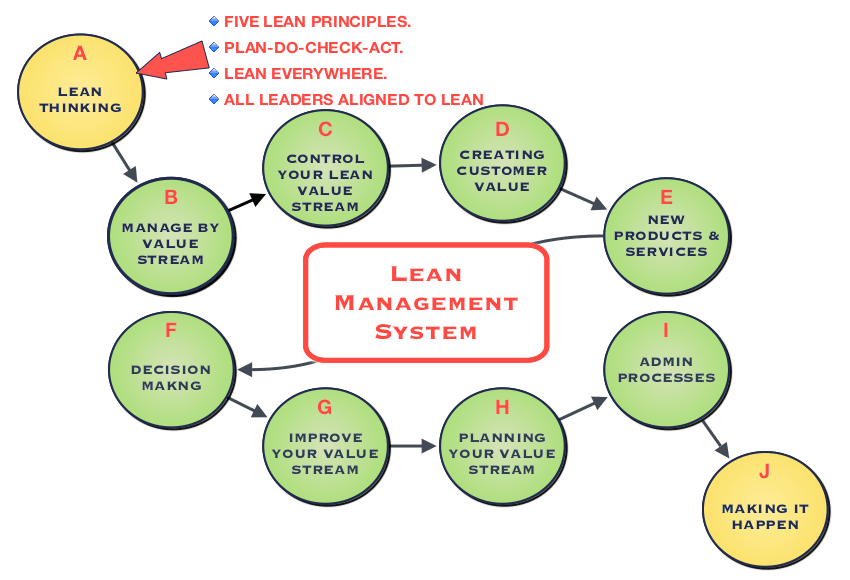

Here’s the big-picture diagram:

When a traditional company has a significant business problem, they call in the experts. The experts study the problem and work out how to solve it. They then develop a project plan with a Gantt chart to show how they will implement all the changes needed to get to their solution†. This same team will parachute into various parts of the company and implement the changes required to solve the problem. Sometimes these projects are very successful, but often they fail or they fail to sustain over time. These projects usually do not get finished on time either.

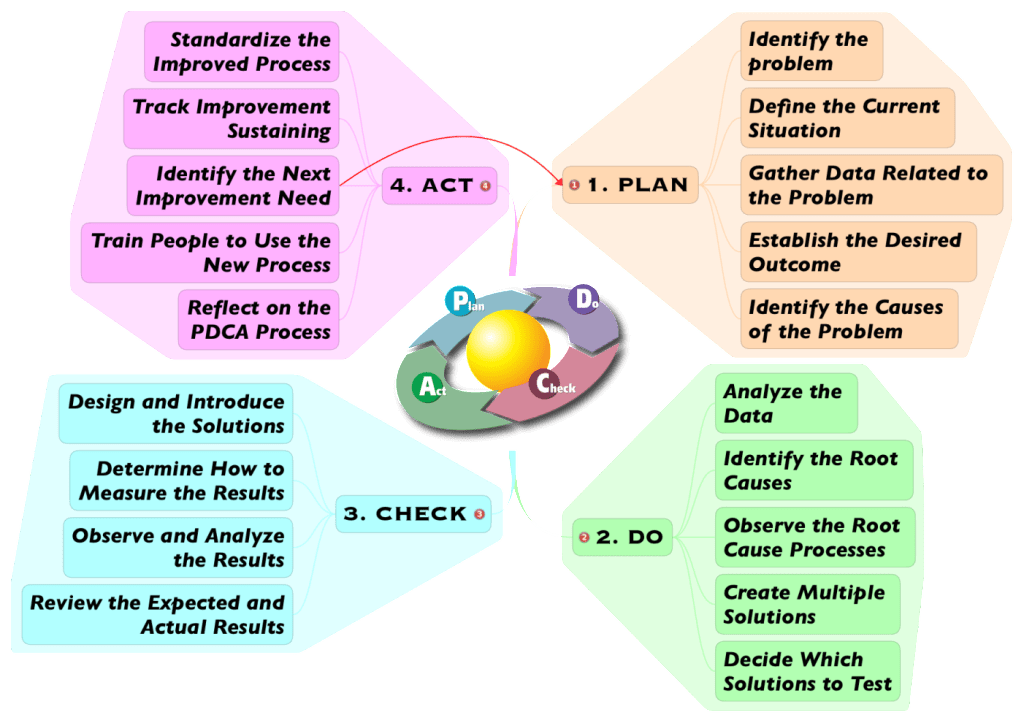

There are two fundamental assumptions at work here. The first is that the experts know what must be done. The second is that the solution can be implemented successfully. Lean thinking rejects these assumptions, and suggests that the problem-solving approach starts from a position of knowing nothing. There are a variety of lean-style problem-solving methods, and the most common is called PLAN-DO-CHECK-ACT (PDCA).

All lean thinking and change is based on data, rather than expertise. We never go into an improvement event with a plan of how to achieve the improvement. We know what problem must be solved, and we know how much improvement we want to achieve. We then step through the PDCA process and make the changes that the team has proven to be the most beneficial.

- The PLAN step identifies the problem, specifies the level of required improvement, and gathers data related to the problem.

- The DO step is where the team analyses the data, identifies root causes, and develops multiple solutions.

- During the CHECK step the team experiments with the most promising solutions, measures the results, more deeply understands the process, and decides which changes will be implemented.

- The ACT step formalizes the changes through standardization, ensures sustainment, and identifies the next needed improvement. There is also a reflection time where the team reviews their work and identifies what new knowledge has been created during the improvement.

- The process is then repeated to build on the knowledge. People learn through repeat practice. Many small projects built around data, analysis, and experimentation.

Companies using PDCA make faster and better improvement progress and they formally capture learning/knowledge that can be applied throughout the business. Companies that do NOT rigorously use PDCA (or similar methods) soon revert to the traditional “expert driven” method of improvement††. This results in slower improvement, fewer successful projects, lack of formal knowledge capture, and the same old top-down projects that do not empower the people in the company†††.

While PDCA is a superior method of problem solving, the more important issue is that lean companies do not start off with a plan of what changes to make. They know clearly what they need to achieve as a business but they do not prescribe solutions. The important changes develop through the PDCA approach based on data, experimentation, and standardization. The work is NOT done by distant “experts” but by the people working day-to-day in the processes. These may be sales processes, production processes, child care, patient treatment, accounting, administrative, and all other processes within lean organizations.

IT IS ESSENTIAL FOR LEAN TO BE APPLIED EVERYWHERE ACROSS THE COMPANY

The methods of lean and the PDCA process must be used throughout the organization. Many companies approach lean half-heartedly and only use lean methods in the operational processes; the factory, the clinic, the construction site, the software developments, etc. True lean includes the use of lean thinking and methods in every process and every location throughout the company.

I sometimes work with companies where only some of their locations are “going lean”. Equally common is for the lean work to be happening in the factory, but sales (for example) are not involved. This leads to dysfunctional flows and a focus on cost-cutting instead of growth. Similarly, if the factory people are working with lean thinking but the accounting and measurements are traditional, the performance reports will push back against lean improvement because the measurements will drive anti-lean behaviors††††.

Lean thinking requires a broad application of lean across the entire organization using a formal PDCA for problem solving and improvement.

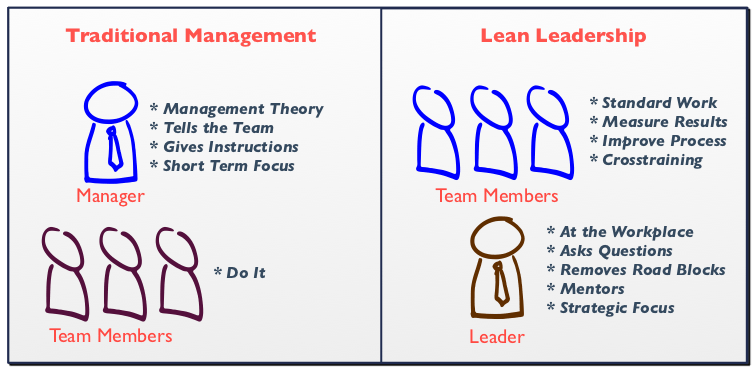

LEAN LEADERSHIP AT EVERY LEVEL

All important things take leadership, and lean is no exception. Lean thinking is entirely the opposite of traditional management. It takes leadership to change the deeply engrained paradigms.

When lean first came to the West in the 1980’s, it was largely run by leaders in the factory. As time went by and people recognized that there was something far deeper going on than just different manufacturing practice, the pressure came to make lean a process that is led and managed by the company’s most senior leaders. There are many lean failures when the people “in the trenches” pursue lean without the understanding or support from their senior leaders.

More recently, it has been seen that in order for lean to prosper, ALL company leaders need to be actively leading lean. Everybody from the executive team, the front line workers, and the middle managers at every level must be fully aligned. Alignment with lean means consistent understanding and lean thinking across the entire organization.

Now, life is not as clear cut and simple as this suggests. But the companies that become lean powerhouses are the ones with full focus and alignment on lean thinking and methods.

SO … LEAN MANAGEMENT STARTS HERE:

We have set the scene for the lean thinking needed for a Lean Management System.

- True lean starts with the Five Principles of Lean

- Focus on Customer Value.

- Work by Value Streams, not Vertical Departments.

- Make Everything Flow without Stopping, at the Pull of the Customer.

- Everybody Works On Lean Improvement.

- Pursue Perfection. Lean is a Long Term Strategy.

- All lean improvement succeeds from data, analysis, experimentation, and control. No one knows in advance what to do; the PDCA process takes us there.

- All our leaders must be trained, aligned, and focused on lean thinking at every level and position.

- Lean must be on-the-go at every part of the company, all the time.

By Brian Maskell

Consultant in lean accounting, lean management, and company-wide lean transformation since 1992. My company BMA Inc. focuses on lean accounting and lean business systems because our experience is that lean transformation is not sustainable if the old management methods, tools, and ideas are not also transformed by lean thinking. Author of more than 8 books including “Practical Lean Accounting”, “Lean Business Management Systems”, “Making the Number Count”, “Performance Measurements for World Class Manufacturing”.

Consultant in lean accounting, lean management, and company-wide lean transformation since 1992. My company BMA Inc. focuses on lean accounting and lean business systems because our experience is that lean transformation is not sustainable if the old management methods, tools, and ideas are not also transformed by lean thinking. Author of more than 8 books including “Practical Lean Accounting”, “Lean Business Management Systems”, “Making the Number Count”, “Performance Measurements for World Class Manufacturing”.

Connect with Brian on LinkedIn | Visit Website

Footnotes:

† Project management Gantt charts usually cannot be read by people over 40 years of age. Is this a conspiracy against us?? Is it “ageism”?

†† This “expert-lead improvement” goes back to Frederick Taylor and the Scientific Management movement of the 1920’s.

††† Dan Jones focused on two primary issues at his keynote for the Institute Lean Paris Conference 2014. “Engage everyone to do things they could not previously do” and “Learning through problem solving and repeated practice.” http://www.youtube.com/watch?v=xqceUgpIKOg

†††† These traditional measurements and accounting methods were designed for 1950’s mass production-style management that, in turn, was developed from Taylorism. They are NOT bad or wrong. They are just designed for a management system that is the opposite of lean.