Engage all employees in solving daily problems

Surely in today’s market of complex and relentless business challenges everyone in an organisation needs to take on the responsibility of solving workplace problems and this requires a formal structured approach. If you were to ask 20 random people within your organisation to spend ten minutes and write down what is their approach to solve simple daily business problems, what would the summary show? Without a structured approach employees will waste precious time focusing on symptoms and therefore implement inappropriate solutions. When you solve for a symptom you don’t solve the problem – the problem persists affecting productivity both internally and externally.

Regardless of the experience level of the employee most professionals feel compelled to jump to the answer and not apply the upfront critical thinking in order to identify the true problem at hand.

Quite often, organisations experience the following:

- Problems that they just can’t solve. Workarounds are the norm.

- Solving the same problem over and over again.

- Significant or repetitive complaints from customers (external/internal).

- Areas of performance that are generally below the desired standard.

- Significant time discussing problems without using data, a formal structure and without resolution

These are all examples of the chronic condition of chasing the symptom and not executing a formal problem solving process to understand those symptoms, uncover the root cause and repair it. Only solving the symptom costs the organisation significant time / money.

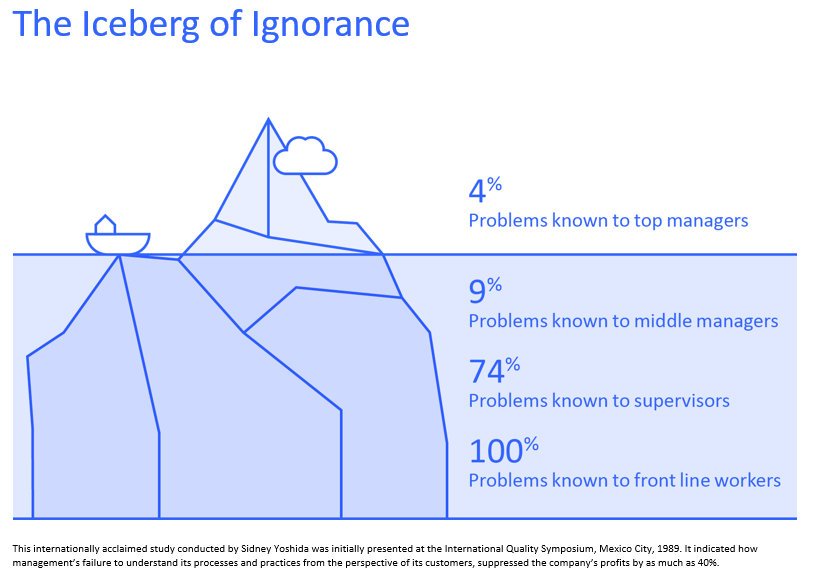

Also, if we take note of the message from The Iceberg of Ignorance, it shows that all operational problems are known by the front line workers and their supervisors. Knowing this – do we give them a method and skills to solve these problems? In the vast majority of organisations we don’t.

But there is a way to change the mindset, to leave behind the symptoms and identify and attack the true root causes so that problems are solved robustly, workarounds are avoided and processes are fixed.

Training all members of these organisations in the common techniques used in problem solving can reverse those losses and start to change the organisation’s culture. Success cannot be sustained without developing an army of problem solvers throughout the organisation. Limiting problem solving to a select few experts, as is often the case with initiatives like Lean Six Sigma, prevents creating a culture where everybody improves the work they do every day. It is a fantastic way to engage all employees in something that is valuable for both the organisation and the employees themselves.

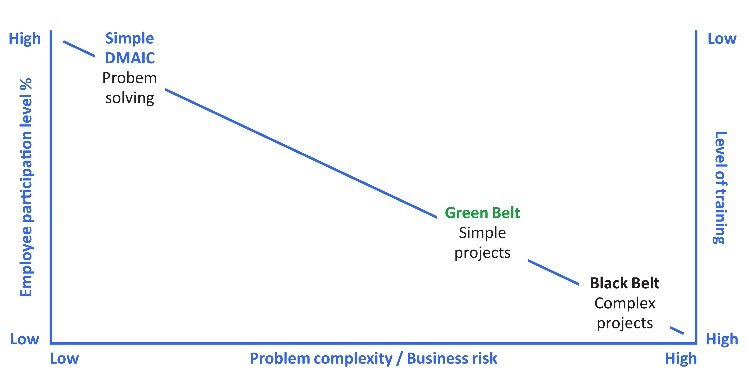

An organisation wide initiative engaging all employees in a standard problem solving process based upon a very simple version of Lean Six Sigma DMAIC is an innovative way of approaching this. It allows for all employees to be able to embrace the basic application themselves as well as understanding the bigger picture.

“Where there is no standard, there can be no improvement.” – Taiichi Ohno.

This quote is used frequently to emphasise the importance of standardised work such as systems and work processes – but it is also important to have a standardised problem solving process across the organisation.

We talk about ‘Process Excellence’ assuming that the only processes that we need to make excellent are the daily operational ones that make the business work, but surely any organisation should consider a structured problem solving process (and supporting skills) as a key process that should also be ‘excellent’ so that when problems occur all employees have the ability to put them right quickly and robustly.

Deploying a very simple version of DMAIC provides a very light but effective method to leverage the strengths of LSS to all employees. Not only does this engage all employees in a common language but it also provides them with the skills to really make a difference to the everyday performance of your orgainisation. It should be:

- Easy to train via a Train the Trainer approach so all levels across the organisation are trained

- Supported by a people change model to ensure that the skills learnt become habit

For those that already have Lean Six Sigma Green/Black Belts it is totally complimentary and will add further value and impetus to those programmes. For any size organisation which wants to embark on LSS deployment this is an innovative way to engage employees faster and more cost effectively – more like a ‘bottom up’ approach that can expand into Green/Black Belt training if required.

In the 1980’s and 1990’s, many companies introduced Total Quality Management (TQM) which introduced the culture, attitude and organisation of a company that strives to provide customers with products and services that satisfy their needs. One of the areas of TQM was in employee teamwork – Quality Circles, a participatory management technique that enlists the help of employees in solving problems related to their own jobs. Circles are formed of employees working together in an operation who meet at intervals to discuss problems of quality and to devise solutions for improvements. A simple DMAIC based approach focused on problem solving, giving a methodology and a common language can be an enabler to employees (and management) engaging in continuous improvement teamwork.

Driving habitual use – a culture change model

A large scale employee training program would have little payback if it was not supported by a strong change management strategy to drive regular use. Here the powerful and portable change management model recommended is Influencer™ (New York Times Best Seller) by VitalSmarts. This proven, yet simple model can help ensure the behaviour change of employees across the organisation to achieve that vision of all employees using simple DMAIC for problem-solving. It focuses on a few high-level ‘vital behaviours’ that are driven by strategies from six-sources of influence. Understanding these vital behaviours and also the ‘crucial moments’ when they must demonstrate the use of that vital behavior is key – and as these vital behaviours become habit we get the change we need. So the way forward is not just the training but also the change management to go with it and truly make it part of the organisation’s culture.

In conclusion, once a culture of problem-solving has been established an organisation will naturally and intentionally change and processes and outcomes will improve. The most valuable asset in an organisation is the people and people that solve problems approach challenges in a structured way and define the problems better by measuring and identifying root causes. This change results in robust solutions being implemented where 1st line managers can help, understand and prioritize issues and this demonstrates to customers that any issue or problem can be fully addressed.

By adopting a culture of problem-solving there is an increase in both individual and team productivity and this has a tremendous impact on the bottom line where employees, management, suppliers and customers win.

Mark Stewart

In my career I have worked in most functions within an organisation and in most areas of the world, so really understand how a business operates. I am passionate about engaging and bringing the abilities of all employees to make a difference to both themselves and their organisation. If you understand Lean you realise its potential in all areas and all aspects of a business.

In my career I have worked in most functions within an organisation and in most areas of the world, so really understand how a business operates. I am passionate about engaging and bringing the abilities of all employees to make a difference to both themselves and their organisation. If you understand Lean you realise its potential in all areas and all aspects of a business.

As an inspirational trainer and natural ‘people person’ with deep experience in people change models, I now run my own company which specialises in combining basic Lean thinking with people change to offer organisations a model where all employees can solve daily problems habitually. LinkedIn Website