“Why did the Chicken Cross the Road?” an OpEx Answer

This is the story of an animal feed company in Poland and answers the question “why did the chicken cross the road?”

An Interim project for KPI selection and building the Dashboard for Management on different levels.

I am an Interim CFO with 20+ years of progressive experience in Finance. From consulting (audit and advisory – Arthur Andersen) through management positions in multinational corporations (Orange, Cisco Systems, Dell). Now as the Interim Finance Director/Interim CFO helping local companies as well as multinationals such as Viacom, and Cargill to overcome their Central European challenges, one such company was this Polish animal feed producer.

With Tens of reports, hundreds of pages of data each division (function) and branch (geographical) had their own special little reports with their own numbers, sometimes contradicting each other and there were no standards for calculated indicators (different periods for averages, different geographical classifications and product categories). This was the reality I found when I entered a large producer of animal feed. Located in Poland, with over 50 years of history, this state-owned, once listed, with the majority of shares purchased by Dutch company and then subsequently de-listed company had

14 production factories

10,000 B2B customers

4,000 products

1500 employees

It was an extremely complex environment and the company had only 6 board members – 3 of them with over 10 years experience in the company and the other 3 with less than 6 months. I was invited to create a set of reports that would help organize their informational needs and support decision making.

The “All-Company” Monthly Report was a set of meaningless numbers on over 30 pages of A4 paper. There was not a single chart, just numbers that only someone who knew the report had any chance of deciphering. The highly qualified and knowledgeable controlling staff knew this report by heart – but it was extremely difficult to read by management, especially the 3 newcomers.

At the same time, hundreds of megabytes of data were being produced and stored in the ERP system, which whilst relatively modern and capable was only a production system for daily operations that lacked a decent data analysis module.

This would be a dream for any BI (Business Intelligence) software implementation. But this was 2009 and BI was a relatively new concept, especially in Poland. Fortunately, the company decided to make two decisions:

- select the KPIs and design the Management Dashboard for different levels of management.

- Build the Dashboard in a BI package.

Standardization as the first step

It was decided and agreed with the CFO (sponsor of the project), that my task was to understand the existing KPIs, discuss the requirements with the management both at board level and line management and select a limited set of indicators. The drill down capabilities of BI system was understood and therefore would be the ideal starting point for real data analysis.

Starting with standardization and in cooperation with the Controlling Department (experts with years of company experience) and Sales Department standard periods were defined along with new standard product groups. We also clarified the geographic and customer classification i.e. if the factory is in region A and delivers to region B – is it a sale of A or B? And if it sells to a farm in region B but is owned by a Key Customer (they were a separate group, not by geography)? This was not implemented consistently and had to be improved.

KPI selection as the second step

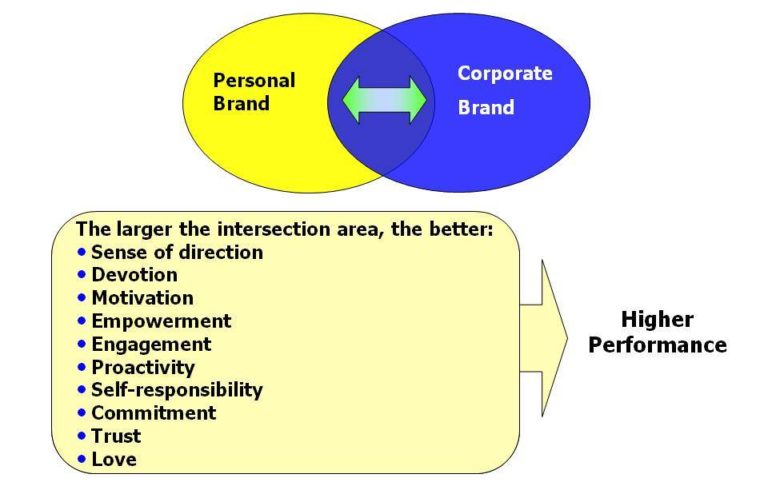

Some time ago my expatriate boss taught me, that a good finance employee must “Understand the business”. I am an engineer by education and it was fun for me to understand the complexity of a large production organization. Understanding the business required not only a review of existing reports but required some travel and talking to employees at many levels of the organization. Japanese theory calls this Gemba – go to the production floor and verify. I did.

Strategic analysis

A great amount of time was spent talking to managers and ordinary employees, asking what is important to them in their decision making. Something unexpected was discovered and this was highlighted for the senior management.

Feed production requires a unique Just In Time delivery technique, and it must be really Just in Time. A farmer normally has limited storage and therefore minimal space for emergency inventory and the storage space he has is only slightly larger than the delivery size. Because of this delivery cannot be too early, for example, 10 tons ordered for delivery on Thursday afternoon may not fit the storage on Tuesday morning. But the delivery cannot be late because animals would either die of hunger or at least lose weight. Just in Time is vital for an animal feed production company.

The production of meat and therefore the market for feed is not really well formalized in Poland, and at the time, the company had about 10,000 customers with none being over 10% of sales in each of 5 regions. The production of feed was not well organized either, the company had 14 production plants spread across the country and there was a dozen of larger producers with hundreds of smaller local ones.

The most difficult Competitors were mostly small local companies: low cost, agile and almost temporary with low investment, small staff sizes who used old, unsophisticated delivery trucks that were owned and that had depreciated some time ago. They were buying grain locally without the need for large storage and long term contracts, contracts were usually financed by delaying payment to the supplier and were therefore virtually free. Local sourcing made logistics affordable and easy and the same trucks were used for logistics in and out, optimizing the capacity of each route. The Lack of long term contracts did not necessarily increase risk because if the feed was too expensive for buyers the producers simply stopped production leaving no inventory of grain and creating almost temporary employees. Farmers stop production once animals are ready (2-10 times per year) and they resorted to buying fodder at higher prices until the end of the cycle. Normally the meat price follows the grain price so the decision to stop production is postponed.

Farming production cycles last several months depending on the animal where chicken grows faster and beef takes longer and most farmers tend to keep the same feed supplier for the entire cycle. It takes an extremely important event to convince them to change supplier outside of a production cycle.

Research showed that there were two types of customers:

long term – a buyer who buys fodder for the current herd regularly

occasional or opportunistic – a buyer who buys this week because his existing supplier is more expensive today, or the supplier does not have the required stock today or the owner/supplier took a vacation and closed the business temporarily.

Each should be treated differently with different pricing structures and different delivery priorities and policies. However this was not done and the company rewarded salespeople for “new” customers, even if they were only opportunistic ones and this led to all customers costing the same to acquire and thus margins on sales were not optimal leading to a variety of issues in management.

10000 customers had 4000 products available in the price list. While it is understood that ruminants need different fodder than horses, and cattle need different fodder than chicken, and egg-laying hens need different fodder than chicken produced for slaughter, it is nonetheless extremely complicated when you produce feed for 40 “categories” of animals. Practically all feed was “made to order” a luxury few industries can afford, there was an attempt to pre-package some standardized feed aimed at specialized retailers but that would have required a diversion in manufacturing processes, a large inventory to begin with, considerable working capital and resellers were reluctant to take on the product because of higher price.

The company had their own farm, where they tested the newly developed feeds, breeding various animals to allow for new formulations and recipes that could be added to the product line. Historically, and the company had over 50 years experience, a number of regional variations remained in the price list because-because grain in the south may be drier in the South and in the damper in the north which added some complexity to the processes. Despite regional issues with varying grades of grain, it was probably possible to reduce the number of products by half. However, even with standard KPI sets for production this still looked excessively complicated.

With the industry understood One important Question remained

What are important issues that motivate farmers to change their feed supplier? Or Why did the chicken cross the road?

One of them is as simple as the delivery time. Understanding the farming processes and ensuring delivery times fit in as required. For example, Egg-laying hens living in buildings with only artificial light are cheated and their day and night is less than 24 hours. Because hens think it is morning after dark they lay another egg and thus egg production increases to more than one every 24 hours. This simple process means that a farm has 10,000 hens that sleep during the day and when the truck delivers feed it makes noise that disturbs the hens and in turn disrupts the egg laying cycle. This results in a material loss for the farmer as hens may not lay eggs the next morning or they may injure each other in the dark when disturbed in their night. Delivery time is very important.

When a producer understands that they must deliver Just in Time they normally focus on improving logistics. But this company focused on price to beat the competition, product excellence on 4000 products and cost of production and then Deliveries were outsourced the delivery to the cheapest supplier defeating everything else in one blow. With all this there was no single report with KPIs for the quality of delivery which with farmers is a key decision-making factor, the only cost measured when it came to delivery was a cost per kilometer.

Reporting was worse in the ordering system as there was no field for entering delivery time , only a date. There was also no way of reporting on the loss of a customer and thus the company often blamed the outsourced delivery company. Despite delivery being a key reason to change supplier the KPI of delivery was not taken into consideration for performance management. The one element that had the greatest impact on customer satisfaction was not measured, it was simply considered OK because it was the cheapest and therefore saved the company money. On top of this, the salespeople were sent to recover the lost customer and were incentivized to bring them back not knowing why the customer was lost in the first place simply to allow the process to happen all over again.

To make matters worse logistics was the only major department that did not have Board Member oversight because technically it was outsourced therefore it did not exist. Delivery was arranged and not really planned somewhere between Customer Service or Order Entry along with the salesperson and Production and Inventory control. The most important element for customer satisfaction did not stand a chance.

With a lot of guidance and a great deal of discussion All it was soon understood that this animal feed company was very much a large logistics company . They purchased over 1 million tons of grain every year and they changed it and then distributed it, they were not just a production company. In the past, it was always cheaper to buy feed from a local producer, but with these companies production and delivery could be unreliable so the company had to change its focus to not just product excellence but also trust and quality of delivery delivering the same product at the right time at the right price and being willing to meet the demands of the farmer.

Unfortunately, these findings were never fully implemented, because Cargill took them over.

However, This is not to say, that the company was totally wrong and illogical, it does prove that someone from outside of the company and industry, preferably with some advisory and consulting experience can see things that seasoned employees cannot see from their silos and ivory towers. It is worth hiring an Interim manager for a cross-functional project and give him a bit of freedom… At your service! Piotr Pikuła.

Piotr Pukula is an Interim CFO with over 2 decades of progressive experience in Finance that has included audit and advisory consulting with Arthur Andersen through to management positions in multinational corporations such as Orange, Cisco Systems, Dell. Currently Interim Finance Director and an Interim CFO helping local companies as well as multinationals such as Viacom, and Cargill to overcome their Central European challenges. LinkedIn