Innovation through Putting New Technology to Work

The Ancestry of Genomic Sequencing Production

I recently received my own DNA analysis results from a company called 23andMe. The very fact that DNA analysis has reached general availability, and that a certain level of analysis is available for under $100 directly correlates to significant decreases in production costs.

First, I do need to state that I am not an expert in the genome sequencing industry. Although I find it absolutely fascinating not just in terms of information systems, the field in which I have some subject matter expertise, but in terms of understanding human evolution and advancements in caring for human kind.

For a view into the evolution of DNA sequencing production one only needs to visit the web site for the National Human Genome Research Institute (NHGRI)

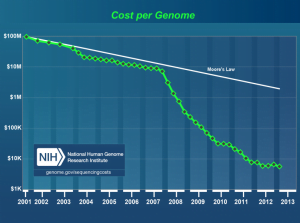

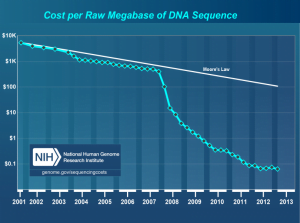

“The Institute has developed a benchmark for measuring the costs associated with production and genome sequencing. Two key measure are (1) Cost per Megabase of DNA Sequence – the cost of determining one megabase (Mb; a million bases) of DNA sequence of a specified quality; (2) Cost per Genome – the cost of sequencing a human-sized genome.”

“The number of transistors incorporated in a chip will approximately double every 24 months.” (Moore’s Law)

– Gordon Moore, Intel co-founder

“Each graph also shows hypothetical data reflecting Moore’s Law, which describes a long-term trend in the computer hardware industry that involves the doubling of ‘compute power’ every two years (See: Moore’s Law [wikipedia.org]).”

In September of 2001, the Cost per Mb was $5292.39 and the Cost per Genome was $95,263,072.

As of January 2013, the Cost per Mb was measured at $0.06 and the Cost per Genome $5,671.

Enabling Moore’s Law with COTS Innovation

Innovations in core processors and technology platforms have played a direct role in the reduction of production costs and the further advancement of technology hardware and software to drive innovation, operational excellence and cost reductions in the industry.

For the genome sequencing industry, and all industries, an enabler of Moore’s law is the transition to COTS (Commercial Off The Shelf) hardware and software. While the upfront investment in a COTS solution can be significant the advantage is economies of scale.

By putting technology to work using a high-quality, design purpose-built COTS solution, sequencing can be done on one system rather than multiple systems – and the costs of downtime can be virtually eliminated.

With advanced design engineering, configuration is automated to eliminate human errors. Mechanical engineering added a cage around the frame grabber, a device used to capture digital still frames of video signals, and to hold them in place in order to mitigate failures and downtime. Extensive stress testing and testing of the data prior to production significantly reduces the opportunity for unanticipated failures. RAID (redundant array of independent disks) added to the server means that production does not stop, because the redundant arrays are a failover system which eliminates the high costs associated with having to restart the sequencing process. By using the customer’s camera and hardware during the build and testing process, technology is put to work to further reduce the chance of unexpected downtime.

In business terms, this represents real operational savings as the size of the service team is reduced and the global foot print of the product is expanded.

What If We Could Replace ‘Bad Actors’ Before They Stopped Working?

With advancements in technology, we now have a predictive model where maintenance can be preplanned on “bad actors” in the field before they stop working. Through a very disciplined approach to software stack management and device monitoring technology, the pain caused by downtime during genome sequencing production is virtually eliminated.

With purpose-built, advanced servers, failure rates on an install base can be reduced by upwards of 50%. This not only drives total operational cost reduction (less service cost). It also increases revenue for many because systems are either leased, or they are generating revenue through the use of consumables.

In terms of the benefits to human kind, the implications of innovations by putting new technology to work are exciting and limited only by our imagination.

By Karen Jahnke

Karen Jahnke is owner and Chief Listening Officer at Triumvirate Consulting Group LLC. As management consultant her passion is to make an immediate positive impact and to deliver a measurable return on investment.

Karen Jahnke is owner and Chief Listening Officer at Triumvirate Consulting Group LLC. As management consultant her passion is to make an immediate positive impact and to deliver a measurable return on investment.

Karen’s philosophy is that successful project delivery is not just about managing the triple constraint. Even when scope, cost, and schedule are managed well the business may not realize a return on investment unless the change impacts to people and process are understood and then managed by an effective change strategy and sustainability plan. Although they sometimes create a natural tension, her view is that project delivery and organizational change initiatives are not opposing forces. In a competitive global economy where businesses are now striving for profits rather than growth, project management that leverages organizational change innovates measurably.

Contact Karen at +1.262.751.2619 or at kmjahnke@triumvirateconsulting.com