Considering Only a Single Perspective Limits Your Point of View to One

We all look at the world from one perspective – our own. The perspectives we hold are born out of the circumstances of our upbringing and further developed by the experiences we gain during our lives. As such, one would expect that the perspective of some who have experienced much in their lives will be wider than one whose experiences have been more limited.

And so it is true for professionals dedicated to Continuous Improvement (CI). Those who are exposed to Continuous Improvement through the disciplines of “Lean” tend to see opportunities for improvement from the perspective of the Lean practitioner. The same is true of those whose training was in Six-Sigma, or Total Quality Management (TQM), or whatever. I find it especially intriguing that each will argue that their approach is the best approach for effecting improvements. However, there are inherent limitations to restricting the approach in realizing improvements – as the saying goes, “If the only tool in your toolbox is a hammer, every problem looks like a nail.” – Abraham Maslow

My experience has been that the fatal flaw of most Continuous Improvement programs and the reason they fail to deliver their potential, is that they marginalize the people in the process – regardless of what might be written in the CI “mission statement” to the contraire. Instead of gaining the trust and engagement of those who will be directly affected by the improvement initiatives, the CI Team usually arrives with a mission for the improvement, affects the improvement without connecting with the people actually working the process, and then immediately move on to the next assignment without even so much as a thorough debrief. The end result is that the CI Team is never fully embraced by those who they are trying to help because they never bother to connect on a personal level, nor is the CI team fully respected by senior management because they fail to deliver the benefits at the expected rates.

So what can be done, what must be done, in order to optimize the CI Program and maximize the net results achieved and to bring them more in line with the expectations? The answer lays in Operational Excellence, which I define as; “Improving the performance of companies and the circumstances of those who work for them.”

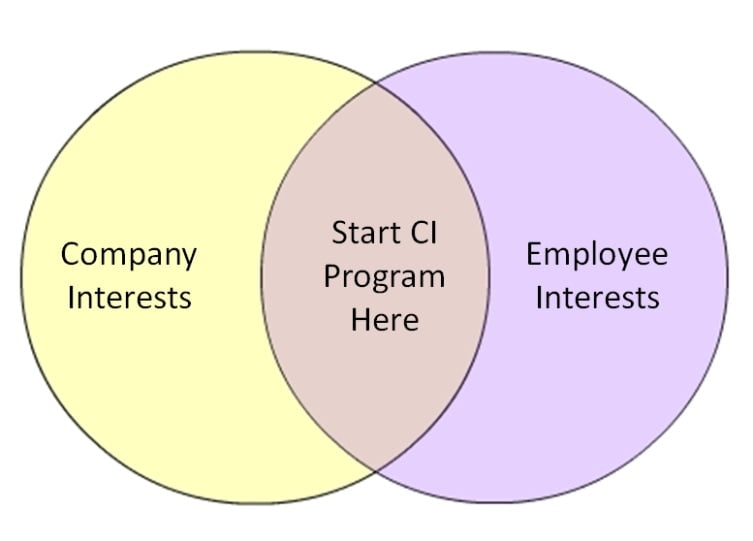

First, we have to honestly and thoroughly answer two questions – both of which have to be answered from the perspective of the subject being asked and not what someone thinks the answers might be or should be. 1) What is important to the company and 2) What is important to the people who work for the company? In essence, we have to answer, “What’s In It For Me” (WIIFM) for both the company and the employees. I do not mean what one person might THINK is in it or someone else, but what is actually in it for that person – from their perspective.

Some examples of what might be of interest to the company (though NOT to be considered an exhaustive list) include: customer satisfaction, increased quality, decreased costs, reduced lead-time, increase in EBITDA, reduction in carrying costs, etc…

And some examples of what might be of interest to the employee include: pride in ownership (ownership of their job or process), recognition for effort, job security, a change in performance measurement from input to output, a company sponsored day-care program, health benefits, etc…

Next, we have to discover the intersection between what is important to the company and what is important to the people who work for the company.

If an honest and objective assessment is performed, this intersection of interests will yield opportunities for improvement where the alignment of company and employee are most natural.

Start your CI program there.

However, you can’t just say, “Today we start our Continuous Improvement program, all-aboard” and assume that your program will be a success. To achieve the true potential of the effort, you have to have the determination to transform your Continuous Improvement program to that of a Deliberate Improvement program – going from making reactive improvements to spotting needs and to a more comprehensive, enterprise-wide, approach to making synergetic, integrated, and proactive improvements. In essence, a culture of transformational improvement must be built across the entire organization.

The key to success for any initiative is to be able to clearly and concisely know what the STRATEGY is, to effectively communicate the objectives to the team in clear and concise language and to align the team so they understand what it is that they are supposed to accomplish. Simplicity in defining your strategy is paramount to success – as Albert Einstein said, “If you can’t explain it simply, you don’t understand it well enough.”

Next, you have to be able to develop the TACTICS for how you will achieve the goals defined in your strategy. Close cross-departmental collaboration is critical as you will need the commitment of those who will ultimately make the dreams a reality. However, it is important to realize that you will never satisfy everyone and that there is no such thing as the perfect plan.Here, gaining trust is a prime objective. People are more likely to support a plan with which they disagree, but with which they were given a fair say, than following a plan that is thrust upon them. As Dwight Eisenhower said, “Plans are nothing. Planning is everything.”

Next, you have to be able to develop the TACTICS for how you will achieve the goals defined in your strategy. Close cross-departmental collaboration is critical as you will need the commitment of those who will ultimately make the dreams a reality. However, it is important to realize that you will never satisfy everyone and that there is no such thing as the perfect plan.Here, gaining trust is a prime objective. People are more likely to support a plan with which they disagree, but with which they were given a fair say, than following a plan that is thrust upon them. As Dwight Eisenhower said, “Plans are nothing. Planning is everything.”

However, ideas will not be realized and plans not put into motion without the LOGISTICS necessary for their support. And herein lies the root-cause of why most CI programs fail – the lack of commitment on the part of the company to support the program. It is folly to expect a company to realize any improvement without allocating the resources necessary to affect the plan in pursuit of the objectives. “Strategy and tactics provide the scheme for the conduct of operations, logistics the means therefore.” – Lt. Col. George C. Thorpe, USMC.

Understanding logistics is the most difficult concept a CI Practitioner must understand. I am not talking about machines or inventory, but the “tools” of their trade. CI Practitioners talk about the “Lean Tool Kit”, or Pareto Charts, or DMAIC. These are all merely tools and not solutions. They are the means to an end – in other words, logistics. In effective problem-solving, it is important to forget the tools and to concentrate on the goals in the context of their environment and circumstance – in other words, in perspective. Once a clear understanding of the opportunity has been made, THEN a solution to realize the opportunity (including the tools) can be developed and deployed. As a rule, never have a logistic in search of a strategy.

Then EXECUTE, and execute as a team maintaining a high-level of communication. For after you have designed, developed, and prepared – after you have thought all the thoughts you can possibly think – it’s time to do. Without the vigorous prosecution of the plan, only mediocrity and failure will be found. If you have excellent leadership with a high degree of communication, you have aligned your resources towards achieving the strategy, and you have complete commitment throughout the organization; the full realization of success will be the result. “Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution.” – William A Foster.

Remember to perform all the above in partnership and with consideration of the circumstances of those who work at the company. Are the circumstances for those working for the company being improved as a result of the efforts of the CI Program? Do they feel like they have an ownership stake? Are they being given the proper support? Or, are they being set-up for failure by – “having responsibility and accountability – but no authority.”

Whether you realize the full potential of your CI Program – or not – depends on how you answer.

About the Author

Joseph F Paris Jr is the Chairman of the XONITEK Group of Companies. With over twenty years as entrepreneur, academic and professional instructor, and strategic consultant – he is a champion of Operational Excellence (Lean Six-Sigma and Leadership) who has devoted himself to increasing stakeholder-value for his clients and constituents.