Escape the Improvement Trap; What Elite Companies Do to Improve

Over the last twenty years, organizations have adopted many different improvement programs – TQM, Re-engineering, Lean, Six Sigma, etc. Despite working hard to adopt/apply the particular improvement methodology, very few organizations actually experience a true transformation and radically improve their competitive position. The competitive position typically stays the same since competitors also advance by adopting and applying the same tools in a very similar fashion.

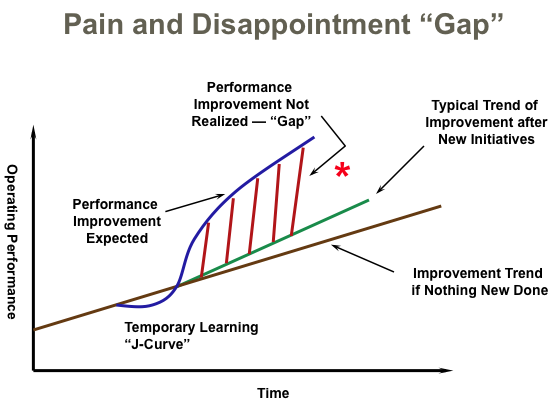

As a result when organizations like McKinsey, Bain, and others conduct surveys asking about the success or failure of an improvement effort, 70% of executives rate their initiative a failure. However, the diagram below illustrates the fact that the efforts are usually not an outright failure.

The organization typically does get better, but since the actual results accomplished are so much less than expected, survey respondents typically fail to appreciate a modest improvement in their trend. So a learning opportunity gets lost.

The Improvement Trap

Our research has uncovered a de facto “trap” that prevents companies from achieving the results they hoped from their business performance improvement efforts. It’s not obvious and takes some explanation.

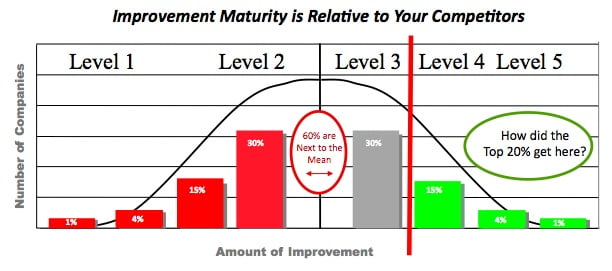

Most organizations do not realize they are merely average, not exceptional, in terms of their improvement maturity and resulting ability to gain market share on their competitors. We simply need to decide on a metric. It’s a mathematical fact that there will be a 50/50 split in terms of improvement maturity for any given industry, with most gathered near the mean.

Why does the trap exist? Companies learn and adopt the ‘Lean Sigma tools’ pretty much the same way their competitors do it. They appoint some smart person to lead the effort. That person finds things to improve, typically using improvement teams to attack waste and remove obvious non-value activities. Meanwhile, the organization does its business pretty much the same way it always has. Things get better, but they get better in the competitors’ companies also, so as a result competitive positions don’t change much.

Unfortunately, the satisfaction of getting better creates an inertia that gets in the way of stretching for truly transformational improvements and new competitive advantage. That satisfaction becomes a complacency that “traps” most organizations at an average level of improvement effectiveness, just keeping pace with other organizations in their respective industry.

Moving Beyond the Improvement Tools

Although the ‘improvement tools’ are important to do well, our premise is the tools alone will not result in transformation. Leadership needs to address five ingredients that are typically weak or missing in most improvement recipes. All organizations to a degree apply the ingredients in our ‘Missing’ list. But most do not go far enough or apply sufficient critical thinking to get a competitive advantage. The most effective organizations in terms of improvement maturity (IM) actively manage the following ingredients.

Commonly Weak or Missing Improvement Maturity ingredients:

- Customer Value – Value drives improvement! Sounds obvious, but many organizations do not have a crisp, clear value proposition that drives key improvement actions. If the Value Proposition is not clear and accurate, nothing else that follows will be crisply aligned. There is an endless list of things that can be improved, but only a handful that will make a competitive difference to an organization.

- People Engagement – Leaders create an engaging environment where people can do their best work; an environment that fosters and facilitates collaborative innovation and execution of the best-known way to do work. Leadership truly respects people and they develop people’s critical thinking skills and abilities.

- Key Metrics – Focus on the vital few, meaningful, validated business-process metrics for the current environment and avoid drowning in irrelevant details. Metrics provide visual, rapid and meaningful feedback at all levels to people inside the organization so people constantly learn how to do a better job of adding value. Linking back to ingredient #1 above, if the overall value proposition is not clear, the metrics cannot possibly be aligned well enough to be better than average, relative to the competition.

- Process Thinking – Process improvement efforts maximize cross-functional process performance and foster deeper process understanding. Most leaders are not process thinkers. It is no secret that customers get served via cross-functional activities. Yet still today most organizations focus more on individual and functional (department) group performance than they do on cross-functional process performance. Dr. Deming stated many times 90% of all performance problems are process problems, not people problems. Yet very few leaders manage their business with this mindset. Outside of a few technical processes (food processing, chemical manufacturing, print quality) very few businesses measure the process capability of their business processes.

- Executive Mindset – This is the glue that holds these ingredients together and provides focus. If leadership is loose on any of the above items (and most are), the company will not rise to the top of its industry in a sustainable fashion. A level 4 or 5 leadership team constantly hones their ability and the ability of their associates to better see waste.

Jeffery Liker, author of “The Toyota Way” and other Lean related books said, “The five ingredients are spot on for anyone serious about performance improvement….” Think about how those ingredients are positioned and practiced in your business. Are they sufficiently performed to move your organization on the pathway to Maturity Levels 4 and 5?

Improvement Maturity Assessment

In the end, the final assessment of your improvement maturity (effectiveness) is your response to two questions:

- Are you doing a better job of getting better this year, than you were last year?

- Have your improvements made a competitive difference to your business relative to your industry as a whole?

If the answer to either of these questions is “No!” then perhaps you can foster more critical thinking inside your organization regarding the five ingredients outlined above and have a more significant impact on the organization’s competitive position.

Michael Bremer is Executive Director of the Chicagoland Lean Enterprise Consortium, a group of Chicago area companies seeking to share best practices, knowledge, and challenge each other to improve, share skill sets, share training, and accelerate learning for leaders and associates of the member companies. Michael is also President of the Cumberland Group a management consulting firm that co-leads critical improvement projects, performs assessments of improvement effectiveness and works with organizational leaders to improve the way their organization improves.

Contact him at michael@cumberlandchicago.com

In his volunteer time Michael is the Vice President of the Assoc. Manufacturing Excellence Award Process. He teaches a class for the University of Chicago’s Graham School, “Better Ways to Work: Innovative Tools for Organizational Excellence.” He has co-authored three books, the latest, “Escape the Improvement Trap” which has received five star reviews on the Amazon Website.