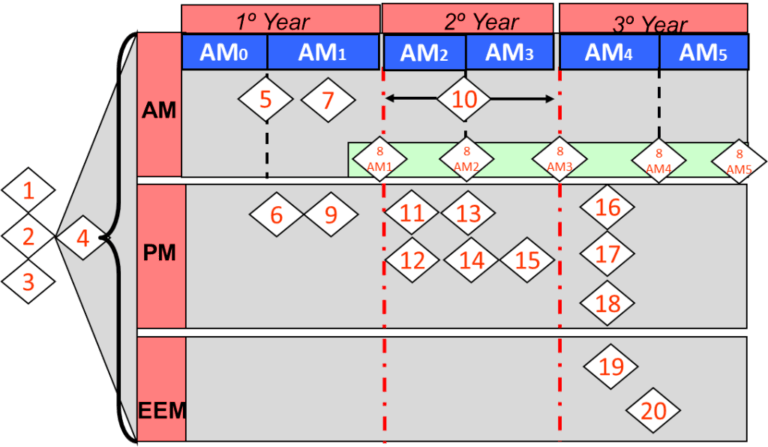

Maintenance that Adds Value to Operational Excellence: “Implementation of TPM in 20 Steps for non-Japanese Manufacturers”

Total productive maintenance (TPM) originated in Japan in 1971 as a method for improved machine availability through better utilization of maintenance and production resources. Within years TPM evolved as a management approach and spread all over the world. T stands for Total, P stands for being Productive, and M is representing Maintenance / Manufacturing / Management….