A Closer Look at Lean Implementation – Part 2

In part one of this article (read here), we discussed the key methodologies of lean manufacturing. In this second part, we would like to discuss: Getting started or improving your current effort in lean manufacturing, plus provide an assessment checklist to highlight your strengths, weaknesses, and opportunities. We will cover four topics important for implementation:

- Getting started: Some precursors and self-assessment.

- The Project Management approach.

- The Business Plan approach.

- Challenges and solutions for success.

- Getting Started, Some Precursors, and self-assessment:

The purpose of a business is to make a profit and to satisfy customers. Therefore, any action plan to implement lean manufacturing for the purpose of achieving operational excellence must, in the end, achieve or enhance this purpose. All the tools we discussed in Part 1 are the means to achieve this purpose. Remember, Toyota came up with TPS because it had inferior products, which could not compete with Western companies.

Getting Started: First and foremost you need to communicate why you wish to start this journey; but if you have already started, you need to communicate where you are today and the next steps on the road ahead. There are many reasons why an organization wishes to move towards operational excellence. We list a few: an enlightened chief executive; a company in a crisis situation; to increase profit.

So how do you start? If you already have TPS or Lean program – look for opportunities to fine tune and excel. Hence, review current initiatives, strengths and weaknesses, and decide how to fill the gaps. If you are just about to start a Lean Program, you need to understand your current situation. In either case you must conduct an overall assessment to understand your current status. The best method is to start by taking an overall look at the entire operation and understand strengths and weaknesses. Initially, focus on the whole and not any specific areas to improve. Start with a gemba walk of each operation. Look, observe, and ask questions:

- Is the workplace organized or cluttered? Is it clean or untidy?

- What type of waste can you see? Clogged aisles? Too much inventory in the warehouse or WIP on the production floor? Too much travel or motion by operators?

- What is the production yield? Is the production defect rate high? Are there boxes of product awaiting rework?

- Are there bottlenecks on the production line? Are the lines balanced or is there operator waiting-time?

- How was the factory layout determined? Is the layout equipment based or product based?

- Is equipment running smoothly? Does equipment breakdown and result in defective assemblies?

- Is there a need to increase capacity? Can reducing variability in the factory increase capacity? For example variability due to batch production, lack of TPM, long machine setup times, high WIP, incoming vendor defects, unbalanced lines, excessive overtime? Look at variability before you consider new equipment.

- Are there robust metrics to measure factory performance? How are you performing to those metrics? Metrics should include: cost, delivery, inventory, productivity, quality, and customer satisfaction.

- Do you have a strong team of engineers, professionals, supervisors, technicians, and operators to manage the business?

- How is delivery to customers? Are you meeting commitments? Is there potential for improvement?

- Are there customer issues that need to be addressed? How serious are the customer complaints?

- Assessment Checklist: A detailed assessment checklist is attached below and will help you with a better understanding of your strengths and weaknesses; it will also help you focus your energy and next steps.

Educate and Train: The next step is to educate and train the manufacturing team in the tools. At this point, it’s best to provide training for senior managers to discuss the key methodologies from this text. Once you move into specific projects, more detailed skills training will be required.

Appoint a Facilitator or Sensei: Appoint a facilitator to help steer the transformation. The facilitator will help monitor and discuss issues and problems and help keep the team on track and schedule, plus arrange to get outside help when required. The facilitator or sensei should be a manager with experience in Lean Manufacturing. The sensei’s role includes:

- Help in the overall assessment of your operation or factory to identify opportunities.

- Provide a deep understanding of the tools: PDCA, and the lean toolbox

- Challenge the team to select aggressive improvement targets.

- The Project Management Approach

We have seen progressive operation managers start working independently on transforming their operations. Hence, this is one way to get started: Select an operation in crisis or one needing improvement. For example: an operation with high customer complaints, high defects, or high costs.

Appoint a Project Team and Lead: Once the area for improvement is selected, it’s time to appoint a project team. Project team members should come primarily from within the team and must include both engineering and production staff. A project leader is also desired, typically an experienced manager in the operation who commands respect.

Conduct an assessment as outlined above.

Work on the Most Critical Issue: Review the areas of customer or management concern. After you have selected a critical issue, analyze the problem, and prepare an action plan. Ensure you define a project size that can be completed in a short time frame of about three to six months. Results in a short timeframe will encourage and motivate the teams and provide more management support. Here are some potential crisis situations:

- Defect rate too high. The defect rate experienced by customers or internally is too high leading to high rework and cost. Review the issues, get to root cause, and execute solutions, bring defects down – aim for 50% reduction.

- Late deliveries or missed shipments. You are not meeting the production plan. Potential problems impeding throughput could be: Defective products requiring rework; Defective material or delays in incoming material; Production line not meeting target production: The production line has bottlenecks; lack of JIT manufacturing, and continuous flow (because of batch production); Machines giving insufficient output.

- Work on the next issue. Select the next project and continue with gains and success – look at other waste and costs. This approach sets priorities and breaks the implementation into manageable and focused chunks of activity. Often you can work on several projects simultaneously − this is dependent to the project size and resource availability. Value stream mapping (VSM) can be used in the project management approach. VSM can help you analyze the areas you wish to improve; after analysis you can use the appropriate methodology to improve.

The biggest challenge with the project management approach is that it is disconnected from the business plans, budget, or resources. Sometimes the project may be going in one direction, while the business is going in another direction. Managers who are already stretched may consider the project management approach as extra work. This is one of the reasons why lean/TPS programs fail. Therefore, it is critical that the efforts are linked to real business and customer needs. Still, if the management team is committed, enthusiastic, and looking at customer and operational needs, the project management approach will work.

- The Business Plan Approach

An alternative approach to getting started is to integrate the transformation into the annual plan. If your entity has an annual business plan, then it is appropriate to consolidate the improvements into the plan. It could be your operation’s specific planning process or the Hoshin planning process, which we have used for years.

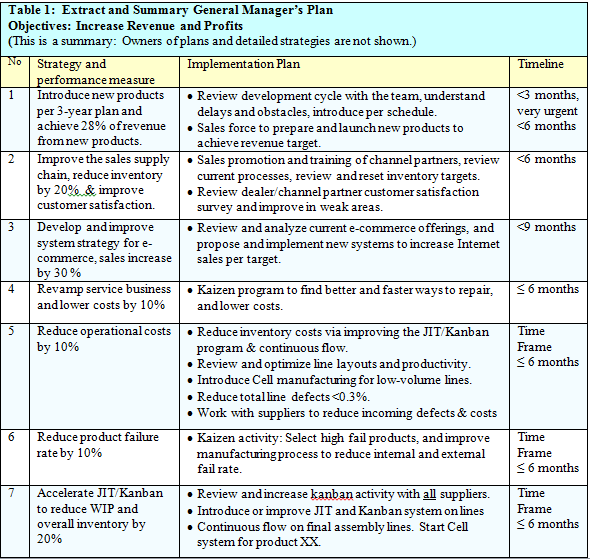

Integrating your lean manufacturing initiative into your business planning process will ensure you do the right things (as opposed to doing things right), such as: review customer needs, evaluate company needs, set priorities, define plans for improvements, and increasing revenue. Table 1, is a summary from a General Manger’s plan. The objective is to increase revenue and profits. The required strategies are summarized in the Table. Some comments:

- The focus is on resolving a critical business issue. There are two objectives: Increase revenue and profits.

- The manager has selected the appropriate tools, which will yield the best results. Some of the strategies will be from our toolbox. In this case, JIT/Kanban and continuous flow can be rolled out or improved throughout the operations. This will also require a full review of cycle time and standard work at all production lines.

- Within this strategy the team can use several tools and methodologies: Get a team to do an assessment and identify opportunities; then use the appropriate methodology, and rollout improvements. Alternatively, use VSM mapping, do the analysis, use the appropriate methodology, target the future state, and rollout improvements

This approach allows you to integrate the relevant Lean methodologies into the organization’s business plan and you are completely synchronized with the organization’s objective and direction. Furthermore, with a detailed business plan, you will be reviewing progress and results during regular reviews. During the reviews, you will be able to adjust and tune your strategies for best results.

Our preference is clearly for the Business Plan Approach, with its focus and deep integration into the company’s business, direction, processes, and customers. The project management approach and the business plan approach are based on our own personal experience; both models have worked for us. Which is the better way forward? The alternatives depend on the structure of your organization, its maturity, and the strength of the management team.

- Challenges and Solutions for Success

We have gone through the tools and methodologies that help achieve operational excellence and we have discussed how to get started. Nevertheless, there are many challenges in transforming an operation towards the new direction. In fact many operations that start a lean and TPS program do not get the expected results. A survey conducted by Industry Week found that only two percent of companies that have a lean program achieved their expected results. Recently the Shingo Prize Committee, which gives awards for operational excellence, checked with past winners and found that many had not sustained their progress after winning the award. Why? We discuss the most critical challenges and provide some solutions from our personal experience. This will also serve as a guide to the CEO or senior manager who wants to implement change and take the journey towards operational excellence.

- Long-term management commitment: This is by far the greatest challenge. Results cannot be achieved over the short term. Hence, the management team, per Dr. Deming, must have “constancy of purpose “over the long term in driving towards the company vision and direction.

- Be patient; if you are starting from a low base, then major improvements and impact may take many months or a year – focused projects with results in 6 months will motivate the management team.

- Be aware of insufficient preparation and learning. After one year of struggle, you may decide that “we tried it but it doesn’t work here” and give up; this would be false learning curve.

- If you decide to introduce the Hoshin planning process to drive your efforts, expect at least two years to have an be acceptable Hoshin process; and at least three years to be proficient in the methodology. The same for TOC methodology.

- Be prepared to ensure and implement cultural change: As the tools and projects are implemented, the team must accept and implement cultural change.

- Focus your efforts. We do not propose that you “Implement TPS or Lean Manufacturing throughout the operation”; such an approach is too grand and difficult to implement given you are also running a business and will have many competing priorities. New methodologies must be selected based on customer and internal needs.

- Strike a balance between costs and value. TPS and lean manufacturing started on the shop floor with the goal of reducing waste and cost. But these tools have evolved into providing value to the customer; value such as: Quicker delivery, via faster response time and excellent quality. Hence, don’t just look at cost reduction.

Summary

We have discussed the tools and best practices of TPS and Lean Manufacturing, which managers and employees must learn and practice. The road ahead is tough and challenging, but focus and persistence will give excellent results. A vital point to remember is:

Operational excellence is a long journey but it is not the destination or goal. The goal is: Increasing wealth in your corporation and providing the highest quality and value to your customers.

Assessment Checklist (Excel File)

Extracted from this author’s book: Winning With Operational Excellence. Due to space constraints, our discussion has been short. More details and theory of the PDCA cycle, gemba walks, Jidoka, VSM, JIT, Hoshin, TOC, and can be found in this reference.

By Soin Singh

Soin Singh is Director of Quality at Venture Corporation. Prior to that he was General Manger (Distribution and Supply Chain) at Hewlett Packard. He has a Doctorate in Supply Chain management and has authored several books including: Total Quality Control and Winning With Operational Excellence