The Value Chain of the Future

I believe it might be safely said without debate that the most important date in the history of Supply Chain and Logistics is April 26th, 1956. This is the date that the SS Ideal-X set sail from the Port of Newark in New Jersey (USA). Five days later, when it arrived in the Port of Houston in Texas (USA), marked the beginning of a new era.

It was not the material that was being shipped that made the voyage noteworthy, but rather the manner in which the material was being shipped. For the SS Ideal-X was carrying 58, 35’ aluminum Containers, and this voyage marked the very first time such a means of transport ever occurred

However this revolution was not started by a Greek Shipping Magnate, or anyone else in the sea-freight business. And it wasn’t the brainchild of some Industrial Engineer at the Massachusetts Institute of Technology (MIT), or the result of some think-tank exercise at a management consultancy firm, or a government-sponsored program.

No, this revolution was started by Malcom McLean of McLean Trucking. McLean did not understand the shipping industry, but he did know that if trucking, shipping, and the transportation of goods in general could be integrated, the costs and time associated with moving product would be reduced by a magnitude. So he bought his first ship, the SS Ideal-Xand followed it on with several others as the idea proved successful.

In March of 2007, the Evelyn Maersk was completed. She is powered by a single diesel electric oil engine capable of 110,000hp (81,905kW) with a top speed of 24.5n. She is 1,299ft (396m) long, has a beam of 184ft (56m), a depth of 98ft (30m) and her draught is 52ft (16m). She is too big to fit in the Panama Canal (which is a reason the Panama Canal is being enlarged).

… And she can carry 11,000 containers at one time with a crew of only 13 sailors.

In April 2011, Maersk announced the commissioning of ten (10) “Triple-E” container vessels capable of carrying 18,000 containers.

If all the containers were put on a single train, the train would be over 60 miles (110km) long.

Of course, there have been other developments in Supply Chain and Logistics over the years which have had a significant impact on improving the flow and tracking of product such as: Bar-Code and Radio Frequency Identification (RFID), intelligent conveyor systems, railroad systems and refrigerated box-cars,interstate highways and trucking, Global Positioning Systems (GPS), right-angle fork-lifts and a host of other inventions.

So what improvements might the future have in store for Supply Chain and Logistics?

I often speak on “A Frictionless World” a world where there are no touch-points of information or materials other than those that add value – for all touch-points have a cost, but not all add value in the eyes of the customer. I imagine that in an ideal Supply Chain, the customer would dream a demand (whatever it might be, in any variant imaginable, from anywhere in the world), the item would be immediately generated by the manufacturer, and it would be instantly teleported to the customer – all happening within moments.

… In my minds-eye, I see this as a cross between “I Dream of Jeannie” and “Star Trek”. There are arguably only two dimension to a Supply Chain; Physical and Information – with the physical consisting of primarily what we can evaluate with our senses and the information consisting of primarily what we can evaluate in our mind.

We move product along in trucks and ships – and we store it in warehouses. We move data along in cables and through routers – and we store it on hard disks. These would be examples of the physical dimensions of a Supply Chain.

But what are in the boxes and on the trucks? Where are they coming from and where are they going? What is the significance of that picture? What is it a picture of and when was it taken?

… These are elements of data which, collectively and with context, constitutes information.

To demonstrate, take the number “42”. This is an element of data, but it has no context and no value. If I were to ask you, “What is the significance of 42?”, you would try to associate it with a variety of roots – from it being the result of ׅ*6” to it being “the Answer to the Ultimate question of Life, the Universe and Everything”; and as luck would have it, a great deal more.

So it stands to reason that improvements to the Supply Chain will be incremental and linear along each of these dimensions individually – but far greater and potentially exponential when the improvement involves both dimensions together. It’s the difference between just moving product (or information) more efficiently and a more optimal state of moving the right productto the right places at the right time and in the right quantities – all the while being able to react instantly to changes in the marketplace, perhaps even anticipate those changes.

In pursuit of this optimal state, the Supply Chain Council (SCC) has developed the Supply Chain Operations Reference-model (SCOR). Intended as a standardized cross-industry model for integrating a supply-chain from the “Customer’s Customers to the Supplier’s Supplier”, the SCOR-model was developed by SCC to serve as a guide for architecting all aspects of customer demand across the supply-chain.

It is obvious that the key to this model’s success is in the real-time sharing of information across the entire demand-chain. It is also the model’s “Achilles Heel” as it requires companies to be open and transparent to both their customers and their suppliers. This necessitates a high degree of trust among and across partners – first, that the information will remain “eyes only” and for the privy of only those who need access to the information (and not competitors); and second that the reaction to information that is outside of expectations does not result in an incessant cacophony of alarmed telephone calls, emails and supplier-hopping. Yes, for this model to be achieved (and achievable), the alarmist nature of the human beings making subjective decisions on objecting information will have to be managed.

According to and Executive Report on Supply Chain Management from The IBM Institute for Business Value entitled, “New Rules for a New Decade (2010)”, there will continue to be an emphasis on “outsourcing”, “optimizing pipeline inventory” and “optimized cost structures” with 50% of the survey respondents either having embarked upon such initiatives or planning to embark in the very near term (within 2 years or by 2012). A further 25% of respondents indicated that they would launch such initiatives in the short term (in 3 to 5 years or by 2015).

What form these improvements take will depend upon the nature of the product or services being provided as well as the marketplace and customers they service.

Obviously, these initiatives will require an increase in timely and transparent information being detected, collected, and evaluated with as much automation as possible – and then routed to an analyst for review and decision. As with product, this will require the right informationbeing discerned through all of the noise that exists, the right assessment being made, and then ensured that it is channeled to the right Supply Chain professional to make the final determination as to the right course-of-action.

The demand-generation for all of this effort is the increased requirement of customers for: velocity of fulfillment, agility to quickly change direction as markets demand, and an exactness of the information and what it means to those consuming the product and services.

For those on the supply-side of the equation, it will require the synchronization of fulfillment assets and resources and a harmonization with respect to the collecting and passing of relevant information in a timely fashion to those who are in need.

Over the next few decades, there will be continued integrations within the physical systems and within the information systems which will result in incremental benefits to the Value-Chain as a whole. But the ever-increasing convergence of the physical systems and the information systems until they are one and the same – so that the best attributes of each are leveraged and the least desirable attributes of each are mitigated – is where the benefits of the optimal state of the Value-Chain will be realized.

I am not certain what form the “next big thing” in Supply Chain and Logistics might be, but in the inescapable world of the global marketplace, it will demand an ever-increasing level of transparency and trust.

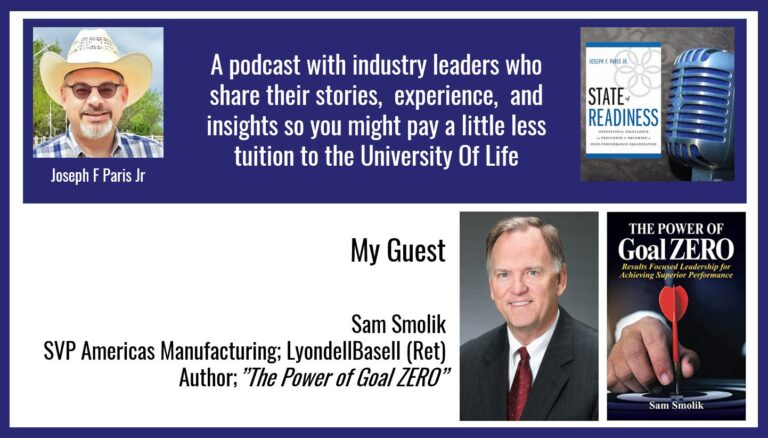

About the Author

Paris is the Founder and Chairman of the XONITEK Group of Companies; an international management consultancy firm specializing in all disciplines related to Operational Excellence, the continuous and deliberate improvement of company performance AND the circumstances of those who work there – to pursue “Operational Excellence by Design” and not by coincidence.

He is also the Founder of the Operational Excellence Society, with hundreds of members and several Chapters located around the world, as well as the Owner of the Operational Excellence Group on Linked-In, with over 25,000 members.

For more information on Paris, please check his Linked-In Profile at http://de.linkedin.com/in/josephparis