OpEx Society – Egypt Chapter – 11 February 2017 Meeting

In this issue:

– KAPCI 4 year LEAN Project

– Bel Sustainable Manufacturing Model

– Supply Chain Excellence Conference in March

– Volunteering role of OPEX Egypt Chapter members

It gives us a great pleasure when we see new members joining our monthly meetings as an indication of our community getting bigger especially this meeting we enjoyed a group from steel manufacturing company and a number of fresh graduates and senior students in Engineering faculties.

We have been using different platforms to promote our activities and announce topics of our meetings. Many people were curious to know how KAPCI managed to implement LEAN in its factory and details of the successful ongoing project. As Egyptians, we tend to start a project enthusiastically then it fades away. In industrial sector, the challenge is bigger due to the diversity of workers cultural and educational background. Normally, resistance to change is huge. KAPCI team represented in Eng. Mohamed El Sayed and Eng. Ahmed El Agami gave us insights  of the project and was complemented by Eng. Mohamed Abdel Latif giving us how Bel Egypt sustained LEAN success in its cheese and cartoon factories. Both sessions were highly interactive and ended with a brief on the coming conference on “Supply Chain Excellence” in March and a quick communication of OPEX Egypt objectives especially to new joiners and inviting them to volunteer in free session to be provided to Egyptian Engineers Syndicate and Faculties along with the initiative made by Symbios Consulting.

of the project and was complemented by Eng. Mohamed Abdel Latif giving us how Bel Egypt sustained LEAN success in its cheese and cartoon factories. Both sessions were highly interactive and ended with a brief on the coming conference on “Supply Chain Excellence” in March and a quick communication of OPEX Egypt objectives especially to new joiners and inviting them to volunteer in free session to be provided to Egyptian Engineers Syndicate and Faculties along with the initiative made by Symbios Consulting.

I would like to thank our great speakers and also our dedicated members who actively join us and support our OPEX community, Eng. Marwan Mahmoud, Mr. Mohamed Ghareib, Operations Director at LUCRAM, Mrs. Amira Mekawy; Operational Excellence Section Head at Egyptian Steel, Mr. Ahmed Shokry, Corporate Operational Excellence Manager at Etisalat.

4 year LEAN Project and the Journey continues…..

KAPCI chose to implement LEAN 20 Keys project back in 2013

KAPCI chose to implement LEAN 20 Keys project back in 2013  as a coherent system suitable for mature organizations seeking sustaining world class manufacturing standards, achieving high productivity levels and continuous improvement. As per LEAN customs, the project started by a kick off meeting in Port Said attended by the Management team along with most of the employees in the factory if not all.

as a coherent system suitable for mature organizations seeking sustaining world class manufacturing standards, achieving high productivity levels and continuous improvement. As per LEAN customs, the project started by a kick off meeting in Port Said attended by the Management team along with most of the employees in the factory if not all.

Focus in 2013 was on Key 1,2,3 and the factory was split into mini business units, assigning leaders/ coordinators starting with a pilot unit then move to the next and so on. Annual high level meeting attended by Management and at least 10% of the employees especially those leaders of the teams to review the performance of the last year and set the SMART objectives of the coming year.

About KAPCI Coatings:

KAPCI COATINGS was established in 1985 in Kantara. In 2002 the company name was changed from “Kantara Paints and Chemical Industries” to KAPCI COATINGS and started the production in the new site in Port Said.

KAPCI COATINGS is the market leader and the largest producer in Egypt in Car Refinish Sector

KAPCI COATINGS is the market leader and the largest producer in Egypt in Wood Coatings Sector.

Total Number of employees is 1500

Total Number of employees is 1500

Exports to over 48 country including many African and Asian countries , middle eastern and USA

Certified ISO 9001, 14001, ISO/IEC 17025 , 18001 for Safety Management during the period from 2004 to date.

KAPCI Coatings vision is to set a KAPCI production system over their 15  factory. LEAN cost is rather seen as investment and compensated by eliminating WASTE and considering Return of Investment which is about 1:8

factory. LEAN cost is rather seen as investment and compensated by eliminating WASTE and considering Return of Investment which is about 1:8

First high level meeting was attended by Dr. Yoshi Kobayashi and discussion was open to tackle challenges and how employees and workers faced them. Symbios Consultants facilitated this meeting to get the best outcome and ensure commitment of staff to the objectives they set themselves. From 2017 the meeting will be semi annual rather than annual. In Lean alignment of the 20 keys results in improving number of areas , you take overall score of the performance in 20 keys.

Benefits of applying LEAN:

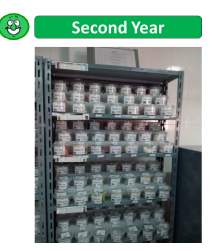

Plenty of examples, Coating industry is one of a dirty industries so it’s a big step to manage and contain source of contamination. Demarkation of storage area, desks, clear pathways, color coding were encouraged and KAPCI workers provided plenty of effective ideas in containing dirt and storing and retrieving materials using colour coding in addition to the serial nos.

Plenty of examples, Coating industry is one of a dirty industries so it’s a big step to manage and contain source of contamination. Demarkation of storage area, desks, clear pathways, color coding were encouraged and KAPCI workers provided plenty of effective ideas in containing dirt and storing and retrieving materials using colour coding in addition to the serial nos.

The worker is responsible for cleaning his one machine, maintain it and improve the way he works. From 2013, Bar code system is applied as part of the ERP system. As a result, the factory is not only cleared and organized but least space is allocated to storage . KAPCI coatings achieved 4S, passed related tests to date and the coming one will be in October 2017 on Excellence certificate.

An interactive session with plenty of questions from our youth attendees on LEAN and details of KAPCI Coatings & Bel Experiences:

Bel Egypt Manufacturing Model

Bel Egypt adopted a BOOST approach of improving ideas, performance control system , identify and eliminate variability. A comprehensive Bel Manufacturing Model BMM that relies on the below pillars:

Bel Egypt adopted a BOOST approach of improving ideas, performance control system , identify and eliminate variability. A comprehensive Bel Manufacturing Model BMM that relies on the below pillars:

The TPM Pillars in BMM:

Bel Manufacturing Model

1. Lean Flow

2. Early management (Product and Equipment)

3. Focused Improvement

4. Education & Training

5. L e a n Office

6. Safety, Health and Environmental

7. Quality maintenance

8. Planned Maintenance

9. Autonomous Maintenance

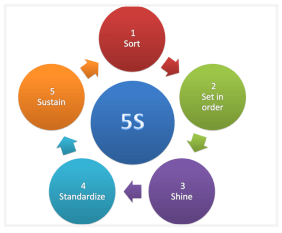

5S + PCS

The company has 2 cheese factories and one carton box  manufacturing factory. While the cheese factories are excellent in hygiene control measures, the carton manufacturing represented the other side of the coin, it was poor facility run by least skilled labor. In 2011 we started 5 S with Symbios as foundation, we set a group of pillars full of tools all the company departments are using as standardized process. The start showed all elements of success; a committed management and team, a competent consultant, an enthusiastic team. The start was strong but 5 months later things went down again due to a number of reasons, one for example; was the leave of an enthusiastic leader, the commitment level dropped and we had to restart all over again.

manufacturing factory. While the cheese factories are excellent in hygiene control measures, the carton manufacturing represented the other side of the coin, it was poor facility run by least skilled labor. In 2011 we started 5 S with Symbios as foundation, we set a group of pillars full of tools all the company departments are using as standardized process. The start showed all elements of success; a committed management and team, a competent consultant, an enthusiastic team. The start was strong but 5 months later things went down again due to a number of reasons, one for example; was the leave of an enthusiastic leader, the commitment level dropped and we had to restart all over again.

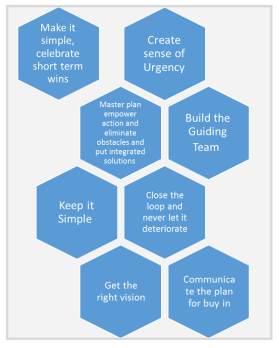

How to Sustain Improvement ?

From Bel Egypt Experience Lessons Learnt/ Recommendations were:

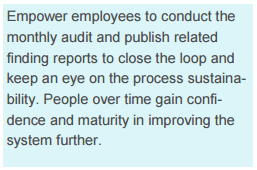

1. Management commitment is not enough to guarantee sustained success without a governance system. Especially in factories running 3 shifts /day , workers need to believe in what they are doing and how they are doing it. Find the believers and empower them to Build the Guiding Team.

2. Vision should not be “Management Made” but rather should be set by a group of workers and should be as practical and achievable as possible. We had to communicate the Vision repeatedly and show how adopting this quality management system enables us to achieve our operational business objectives. We gave plenty of sessions to explain to people how  for example ;clear desk and continuous archiving would help retrieving the data in 1 minute and speed the decision making process or otherwise.

for example ;clear desk and continuous archiving would help retrieving the data in 1 minute and speed the decision making process or otherwise.

3. Keep things logic and simple and adhere to the system or adhere to the process. Consider 5S but think why a worker should clean his working machine, or area, consider monetary and non monetary benefits. You will be surprised that they are equally important.

4. Always praise good work, simple ideas, etc… Announce best worker of the month, or publish an idea and give credit to its provider would enhance his /her self esteem and self pride. Reward is not only financial, moral reward in equally important. Consider both.

4. Always praise good work, simple ideas, etc… Announce best worker of the month, or publish an idea and give credit to its provider would enhance his /her self esteem and self pride. Reward is not only financial, moral reward in equally important. Consider both.

5S+1 Management System KPIs

One of the benefits of a 5S System is it makes the workplace safer.

We encourage all our society members to take part in promoting the society values, actively participate in the coming events and share the knowledge to their communities.

________________________________________________________________________________

Having a tough year which puts you under great pressure? Need to enhance your business performance and looking to control costs and achieve supply chain excellence?

Start the second quarter of the years with the tools that will help you reach your goals while listening other renowned companies’ successful practices. Learn new techniques on how to achieve Supply Chain Excellence with the industry top experts.

Join us on March 11, 2017 at Helnan Land Mark Hotel with a very special price of EGP 500 per person including coffee break and lunch.

For more information, contact us on:

egypt@symbios-consulting.com

magda_elshabrawy@yahoo.com

Tel: +20 1092219663, 01098891700

Fax: +20 223 581 494