Realizing the Value in Business Processes

I had a very busy May with speaking engagements at the Association for Corporate Growth (ACG) NJ Due Diligence Conference followed by the ACG-NY Manufacturing & Logistics Conference and wrapping it up by delivering a paper on Operational Excellence at the Institute for Industrial Engineers (IIE) Annual Conference in Vancouver.

The underlying theme of all of these speaking engagements was the importance of realizing the value in business processes.

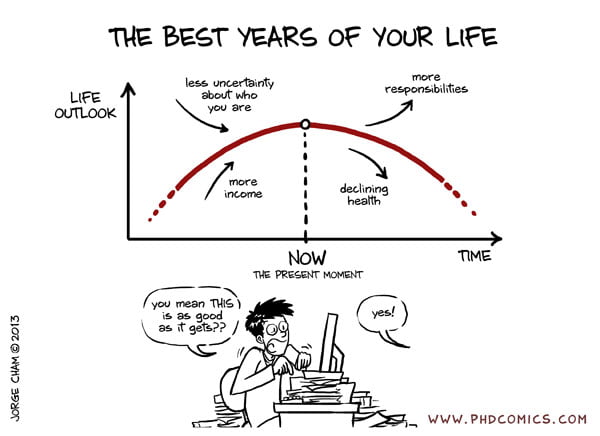

Whether personally or professionally, it is human nature to blindly follow our normal routines – our normal “processes,” without a second thought. We do what we do because “that is the way it’s always been done.” When we do make a change, it is usually a minor adjustment to a spot need or weakness, and rarely a complete re-engineering.

Take your morning routine for example- from the moment we wake, to the moment we are out the door. Most of us have morning routines which take from 30 minutes to 60 minutes. We take a shower and do our bathroom duties, have a cup of coffee and a breakfast, read the newspaper and watch “Morning Joe .”

But on the rare occasion that we oversleep and are rushed – maybe we are awoken by sound of a car horn as your golf-buddy sits in the driveway waiting for us – we are able to get out the door in five minutes.

What’s the difference?

The difference is motivation driven by necessity.

I am not suggesting that we sacrifice our “quality of life” for a more Spartan personal existence, but there is a difference between personal and professional. In our professional world, there is only the quick and the dead.

We have to dependably produce the highest quality product (or service), at the best value, within a very short time. However, it is the word “value” where all of the nearly infinite variables collide and conflict. For instance, is a customer willing to pay more for immediate satisfaction in order fulfillment? Or for production tolerances that are more precise? Maybe they are willing to wait for the delivery for a reduction in the price? Here, “value” is defined in the eyes of the customer.

But many people believe that their production processes are sufficiently oriented to drive value in the eyes of the customer. I can prove you wrong by making this simple challenge…

In your organization, have you ever said, or heard anyone say, “There must be a better way.” I will guarantee you that you have. And if you have, I can also guarantee you that there is.

However, there is a difference between “need” and “want.” To “need,” you just have to recognize that there is a problem or opportunity that requires attention and action. To “want” is to make the decision to do something about it.

Unfortunately, we are usually too engrained in the “way it is” that we cannot see the “way it can be” as we are too close to the problem. All too often, what usually happens is that we react to the moves of our competitors. The truly bold will hire from outside the company (perhaps even outside the industry). Consider the renaissance at IBM (a technology company) when Lou Gerstner from Nabisco (a food company) was hired as CEO to replace a foundering John Akers .

And we can take the present goings-on at Fiat; for example, Fiat , like many car manufacturers, had been struggling for decades. Though not a subsidiary, they were tied to General Motors ( GM ).

In 2004, Fiat turned to outsider Sergio Marchionne, a work-out expert formerly with Societe Generale de Surveillance SA . Marchionne’s first task was to stabilize the finances of the company – which he accomplished by first getting GM to pay $2 billion to sever the relationship. He then parlayed this cash infusion to support a right’s issue, whose proceeds he used, in part, to pay-off bank debts of $4.5 billion. Within a very short time, Marchionne had made the Balance Sheet of Fiat the envy of most peers.

But all of the effort to create a healthy balance sheet will atrophy quickly if you don’t then focus on the customer – and operational and product-line functions.

Seeing a product-line that was dated, tired, and boring, Marchionne realized he had to make dramatic improvements in the “curb appeal” of Fiats quickly. He replaced all of the design engineers with fresh (and young) faces whom he affectionately calls “the kids”. With a new-found freedom from former task-masters and the “old ways” – combined with a sense of urgency, Marchionne and the “kids” were able to introduce new models in 18 months, rather than the industry expectation of 26 months.

Today, Fiat is successful and vibrant. Its products are desired by its customers and its technology is coveted by its peers.

You have to make products (or deliver services) that customers want to buy, at a price that they can afford. You have to consistently challenge the status-quo. You not only have to need help, you have to want help… and very often, it is better to look to the outside for such help.

Related Articles:

Rebirth of a Car Maker. The Economist Magazine. April 24, 2008.

The Miracle of Turin. The Economist Magazine. April 24, 2008.

Paris is the Founder and Chairman of the XONITEK Group of Companies; an international management consultancy firm specializing in all disciplines related to Operational Excellence, the continuous and deliberate improvement of company performance AND the circumstances of those who work there – to pursue “Operational Excellence by Design” and not by coincidence.

Paris is the Founder and Chairman of the XONITEK Group of Companies; an international management consultancy firm specializing in all disciplines related to Operational Excellence, the continuous and deliberate improvement of company performance AND the circumstances of those who work there – to pursue “Operational Excellence by Design” and not by coincidence.

He is also the Founder of the Operational Excellence Society, with hundreds of members and several Chapters located around the world, as well as the Owner of the Operational Excellence Group on Linked-In, with over 25,000 members.

For more information on Paris, please check his Linked-In Profile at: http://de.linkedin.com/in/josephparis